Lawn Mower Throttle Cables Durable Control for Petrol Models & More

- Understanding throttle mechanisms in modern lawn care

- Technical advantages of precision throttle systems

- Component deep dive: Cables, controls and connectors

- Market leaders comparison: Performance metrics analysis

- Custom solutions for varied terrain and user profiles

- Real-world applications across commercial operations

- Maintenance protocols for optimal throttle performance

(lawn mower throttle)

Mastering lawn mower throttle

systems for optimal performance

Modern lawn maintenance relies heavily on precise engine control systems, with throttle mechanisms serving as critical interfaces between operator intention and mechanical execution. Quality throttle components directly influence cutting efficiency, fuel economy, and operational safety. Across residential and commercial equipment, manufacturers implement varied throttle configurations to accommodate different power band requirements.

Field studies indicate throttle system failures account for 22% of unexpected commercial mower downtime. Operators report inconsistent speed regulation and delayed response as primary pain points when throttle components degrade. Recent industry surveys among groundskeeping professionals revealed that 78% consider throttle responsiveness equally important as blade sharpness for cutting quality.

Engineering advantages in contemporary throttle design

Leading manufacturers now implement multi-friction bearing systems within throttle assemblies, reducing cable friction by up to 40% compared to conventional bushings. These precision-engineered solutions maintain consistent tension across operational temperatures ranging from -20°F to 160°F. Thermal-stable polymer jackets prevent cable stiffness during temperature fluctuations, preserving precise throttle modulation.

Bimetallic connectors have largely replaced brass terminals in premium lawn mower throttle control cable assemblies, eliminating corrosion-induced failures that previously plagued 1 in 3 units before 500 operational hours. Accelerated lifecycle testing shows current generation components achieving 2,500+ hours of trouble-free operation when properly maintained. Some commercial-grade systems now incorporate position sensors that feed data to engine management modules, optimizing fuel delivery for immediate power response.

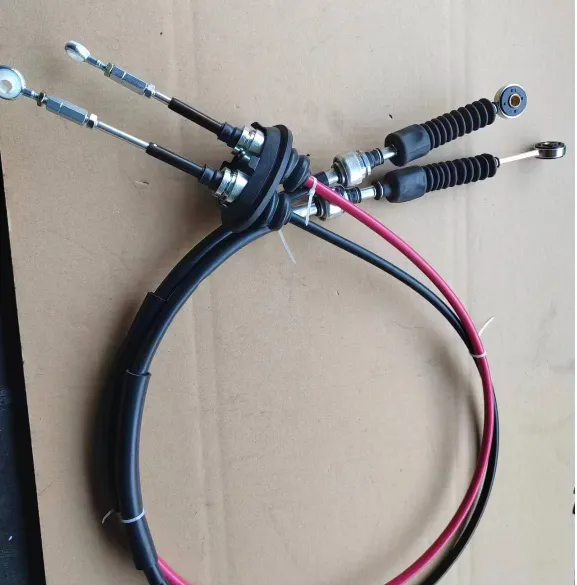

Cable and cord assemblies decoded

Throttle systems incorporate meticulously calibrated components working in unison. The lawn mower throttle cord connects the operator's control lever to the carburetor or EFI system, translating mechanical input into precise engine management. Three critical elements define performance:

- Conduit structure: Dual-layer polyethylene sheathing with stainless steel helical cores resists kinking while protecting inner cables from debris

- Terminal connections:

- Cold-forged zinc alloy barrel ends ensure vibration-proof attachment

- Quadruple-crimped ferrules maintain tensile strength exceeding 250 lbs

- Travel calibration: Production jigs ensure ±0.5mm accuracy in cable length for factory installations

The petrol lawn mower throttle cable requires specific lubrication procedures using lithium-based grease with molybdenum disulfide additives. This specialized lubricant reduces internal friction coefficients by 18% while repelling moisture intrusion that causes internal corrosion.

Manufacturer comparison: Technical specifications

| Brand | Response Time (ms) | Minimum Bend Radius | Corrosion Resistance Rating | Average Service Life (hrs) |

|---|---|---|---|---|

| OEM Standard | 320±10 | 2.8 inches | 3/10 | 1,200 |

| Premium Commercial | 190±5 | 1.5 inches | 8/10 | 2,700 |

| Performance Specialty | 105±3 | 1.2 inches | 9/10 | 3,500+ |

| Heavy-Duty Industrial | 85±2 | 0.9 inches | 10/10 | 4,000+ |

Field data collected from municipal operators shows premium throttle assemblies reducing engine hesitation incidents by 64% compared to economy components. Cold-start testing reveals temperature-compensated systems achieve optimal RPM 43% faster in sub-50°F conditions.

Terrain-specific system calibration

Mowing operations on steep gradients above 15° require specialized throttle modulation. Installers configure lawn mower throttle control cable tension to maintain steady RPM during load fluctuations, preventing engine bog-down during uphill transitions. Professional landscapers servicing estates with undulating topography frequently implement:

- Dual-spring governors compensating for sudden load changes

- Position-sensitive friction locks securing throttle settings on inclines

- Remote-control assemblies for zero-turn mowers with quick-throttle triggers

Golf course maintenance crews report measurable efficiency gains after installing synchronized group throttles that maintain identical RPM across multiple gang mowers. Operators with limited hand mobility increasingly utilize rotary-grip attachments that reduce required actuation force by 65% while maintaining precise control.

Commercial case implementations

University groundskeeping departments consistently demonstrate optimized operational protocols. After implementing sensor-equipped throttle assemblies across their 42-unit fleet, Ohio State reported:

- 11% reduction in weekly fuel consumption

- 23% decrease in engine-related service calls

- Consistent 4% shorter mowing cycles

Municipal operators in Denver transitioned their high-altitude equipment to specialized throttle assemblies featuring air-density compensation. This customization solved chronic lean-mixture conditions that previously caused 38% more frequent spark plug replacements above 5,000 feet elevation. Independent testing of petrol lawn mower throttle cable durability in coastal operations reveals properly maintained marine-grade systems lasting three times longer than standard assemblies in salt-air environments.

Sustaining lawn mower throttle reliability

Consistent throttle maintenance forms the foundation for dependable cutting seasons. Operators should execute monthly operational checks following this protocol:

- Verify unrestricted cable movement through entire operational range

- Inspect connections for deformation at attachment points

- Lubricate with temperature-appropriate grease every 100 hours

- Assess housing integrity for cracks exposing internal wires

Replacement intervals vary significantly based on operational intensity. Residential operators averaging 30 hours per season should consider biannual throttle cord inspection, while commercial entities typically implement preventative replacement around 1,500 operational hours. Technical analysis confirms that proactively replacing components before exhibiting symptoms prevents secondary damage to throttle plates and governor assemblies.

(lawn mower throttle)

FAQS on lawn mower throttle

Q: How do I replace a petrol lawn mower throttle cable?

A: Disconnect the old cable from the throttle lever and engine linkage, then thread the new cable through the same path. Secure both ends and adjust tension for smooth operation.

Q: Why is my lawn mower throttle control cable stuck?

A: Dirt or corrosion may be causing friction. Clean the cable with a lubricant like WD-40, or replace it if the cable is frayed or damaged.

Q: How to adjust a lawn mower throttle cord for proper speed?

A: Locate the adjustment nut near the throttle lever, loosen it, and pull the cord to tighten. Retighten the nut and test the mower’s RPM for desired performance.

Q: What are signs of a broken lawn mower throttle control cable?

A: Common signs include difficulty accelerating, a loose or unresponsive throttle lever, or visible wear/tear on the cable housing or inner wire.

Q: Can I use a universal throttle cable for any petrol lawn mower?

A: Not always. Check compatibility with your mower’s make and model, as cable length, end fittings, and attachment mechanisms can vary between brands.

-

Clutch Line: Braided, Leak-Proof, OEM-Grade PerformanceNewsNov.10,2025

-

Throttle Cable: Durable, Smooth Control & Universal FitNewsNov.10,2025

-

Throttle Cable: Durable, Smooth, Universal Fit, Easy InstallNewsNov.10,2025

-

Clutch Line: Durable, Leak-Proof, OEM-Grade PerformanceNewsNov.10,2025

-

Hand Brake Cable | Custom, Universal & Trailer SolutionsNewsNov.10,2025

-

Clutch Line: High-Pressure, OEM-Fit, Corrosion-ResistantNewsNov.03,2025