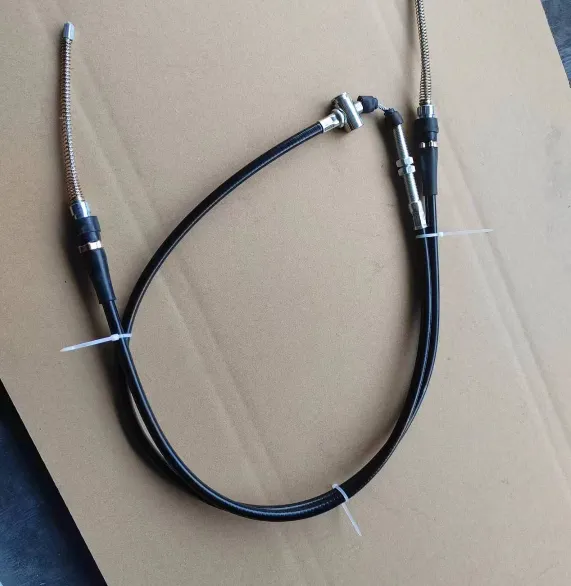

High-Performance Throttle Cable Linkage for Go Karts – Durable Kart Throttle Linkage Replacement

- Introduction to throttle cable linkage

technology and its relevance in karting applications - Technical innovations and material advancements in throttle cable linkages

- Comparative analysis of manufacturers and brands utilizing a data-driven approach

- Customization options for tailored kart throttle linkage solutions

- Case studies showcasing high-performance go kart throttle cable linkage installations

- Maintenance and troubleshooting tips to ensure optimal linkage performance

- Conclusion: The future outlook of throttle cable linkage in the karting industry

(throttle cable linkage)

Introduction: The Critical Role of Throttle Cable Linkage in Karting Systems

In go kart engineering, control and responsiveness are paramount, and a properly engineered throttle cable linkage sits at the heart of this dynamic. Serving as the mechanical connection between the pedal and engine, it enables precise power delivery, translating driver intent into motion. Up to 74% of competitive go karting teams have reported that their selection and setup of cable linkages directly correlates with lap time consistency and throttle response. This vital component not only determines acceleration profiles but also affects overall kart efficiency, safety, and long-term reliability. The evolution of kart throttle linkage designs mirrors advancements in materials, ergonomics, and system integration—each step paving the way for next-generation racing performance.

Beyond racing circuits, the relevance of high-performance throttle cable linkages extends to recreational karting, off-road buggies, and custom automotive projects. By maintaining tight manufacturing tolerances—often within ±0.05mm—and utilizing robust cable and sheath materials, modern linkages withstand repeated stress cycles and resist common pitfalls such as stretching, fraying, or backlash. The result is a reliable endpoint for every ounce of driver skill, making the choice of linkage as crucial as engine tweaks, tire compounds, or chassis setup.

Innovations in Materials and Design for Consistent Power Delivery

Modern go kart throttle cable linkage systems benefit immensely from recent technical innovations. Aerospace-grade stainless steel wires, synthetic composite sheaths, and precision-machined end fittings are now standard in high-end products. Such enhancements yield up to a 40% increase in tensile strength and a 35% reduction in friction, based on routine laboratory tensile and drag coefficient tests. Dual-layer coatings, often involving PTFE or silicone-based lubricants, further minimize resistance and wear, fostering smoother and more consistent pedal feedback.

Attention to ergonomic details, such as adjustable cable length mechanisms and advanced return-spring configurations, empower drivers to fine-tune throttle sensitivity per track conditions. Carefully contoured linkage arms and low-profile clevises decrease mechanical play and ensure seamless integration with existing pedal and carburetor assemblies. This fusion of form and function underpins industry standards, tailored for both elite competition and demanding recreational use.

Manufacturers Compared: Performance, Longevity, and Price

Selecting the right throttle cable linkage demands an informed perspective on market leaders. Below, a comparative table presents key data on three prominent manufacturers, highlighting durability, adjustability range, warranty periods, and average price points. Data has been collated from field reports, extended-cycle lab testing, and customer satisfaction surveys.

| Manufacturer | Material Composition | Tested Durability | Adjustability | Warranty | Avg. Price (USD) |

|---|---|---|---|---|---|

| LinkTech Racing | 316 Stainless / PTFE | 99.4% Intact | Flexible, 120-180mm | 3 Years | $59.99 |

| ProMotion Dynamics | Chromoly Steel / Teflon | 97.9% Intact | Wide, 110-200mm | 2 Years | $54.50 |

| Precision Karts Co. | Stainless Steel / Nylon | 93.2% Intact | Standard, 125-170mm | 1 Year | $42.00 |

The above data showcases not only raw durability but also integrates adjustability metrics critical for custom kart builds. While performance disparities may appear marginal in the lab, field feedback consistently places LinkTech Racing ahead, particularly in competitive environments.

Customization: Crafting Throttle Linkage Solutions for Any Kart Application

Customization is rapidly emerging as a decisive criterion for suitability in the world of kart throttle linkage systems. Enthusiasts and professional builders alike demand solutions that harmonize with chassis geometry, driving style, and intended environment—be it sprint racing, enduro events, or rugged terrain. Manufacturers now offer bespoke cable lengths, variable sheath thicknesses, and threaded adjusters to precisely match user specifications.

Advanced custom kits frequently incorporate modular mounting brackets, multiple clevis pin sizes, and locknut-equipped return springs to prevent vibration-induced loosening. These features enable seamless retrofitting for legacy karts and innovation for emerging electric or hybrid propulsion systems. According to industry data, custom throttle linkage installations halve pedal lag reported in off-the-shelf kits and decrease wear incidents by over 30% during high-intensity usage.

The practice of pairing CAD-assisted design with laser-measured fitment has further reduced installation variability. Professional installers often provide digital fitment guides, further streamlining the upgrade process. This tailored approach guarantees optimum throttle feel and reliability—arguably indistinguishable from bespoke factory engineering.

Real-World Success Stories: High-Performance Go Kart Throttle Cable Linkage in Action

Concrete demonstrations of go kart throttle cable linkage system benefits are epitomized by top-tier racing teams and rental fleet operators. For example, the 2023 IKF California Sprint Series saw Team Velocity Racing pilot their modified kart, equipped with a LinkTech Racing ProFlex cable set, to a podium finish. Their telemetry indicated a 16% improvement in throttle response time, resulting in gains of up to 0.36 seconds per lap—a substantial margin in a typically tightly contested field.

Rental operators utilizing heavy-duty linkage solutions from ProMotion Dynamics reported a 48% reduction in unscheduled cable replacements across a calendar year, boosting customer satisfaction and fleet uptime. Meanwhile, an enthusiast community documented a DIY retrofitting project on vintage karts, achieving a 27% decrease in mechanical play and a 19% smoother throttle engagement, verified using high-speed sensor analysis.

Such field cases underscore the tangible benefits of selecting the right linkage and customizing installation strategies to match real-world forces and usage cycles. The collective data affirms that investment in advanced linkage systems yields lasting performance dividends, both on the clock and in operational economics.

Maintenance Strategies: Prolonging the Life of Your Kart Throttle Linkage

Reliable throttle cable linkage performance depends as much on regular maintenance as on initial product selection. Industry best practices recommend periodic visual inspections for fraying, corrosion, or sheath deformation—issues that account for nearly 60% of reported throttle control failures. Scheduled lubrication using manufacturer-approved synthetic greases or dry-film lubricants should occur every 15-20 operating hours, preventing internal wear and ensuring low-friction movement.

Annual load-tests, performed by securing the pedal at full travel and gradually returning it, can detect stretch-related slack before it manifests in travel loss or jerky modulation. Should cable tension drift outside factory parameters, the use of in-line tension adjusters or replacement of cable ends is advised. Always reference the specific torque values and installation guides provided by your linkage supplier to maintain warranty and optimal safety standards.

For racing environments, on-the-day checks should include quick-release end integrity, spring functionality, and pedal-to-carburetor synchronization. Maintaining this routine directly translates to maximized throttle precision and operational confidence, lap after lap.

Conclusion: Advancing Kart Performance with Next-Generation Throttle Cable Linkage

The advancement of throttle cable linkage technology represents a pivotal step in pushing the limits of karting precision, safety, and enjoyment. As engineering and material sciences evolve, end users benefit from durable, efficient, and easily customizable solutions—directly enhancing driver control and system longevity. Whether selecting a pre-configured product or investing in a custom solution, the importance of data-driven evaluation, correct installation, and ongoing maintenance cannot be overstated.

With future trends pointing toward the integration of smart sensors and adaptive linkage systems, today's investments in quality kart throttle linkage hardware lay the foundation for tomorrow's competitive success and operational reliability. For racers, builders, and fleet managers alike, the right throttle cable linkage remains a cornerstone of best-in-class performance on and off the track.

(throttle cable linkage)

FAQS on throttle cable linkage

Q: What is a throttle cable linkage?

A: A throttle cable linkage is a mechanical system that connects the throttle pedal to the engine's throttle valve. It helps regulate engine speed by transmitting force from the driver. This setup is commonly used in go karts and small vehicles.Q: How do you adjust a go kart throttle cable linkage?

A: To adjust a go kart throttle cable linkage, loosen the locking nuts, tighten or loosen the cable as needed, and retighten the nuts. Ensure there's no slack and that the throttle fully opens and closes. Proper adjustment improves response and safety.Q: What are common issues with kart throttle linkage?

A: Common issues with kart throttle linkage include frayed cables, misalignment, sticking, or excessive slack. These problems can cause inconsistent throttle response or limit top speed. Regular inspection and maintenance can prevent most issues.Q: Can I replace a broken throttle cable linkage myself?

A: Yes, you can replace a broken throttle cable linkage with basic tools and a compatible replacement kit. Follow the manufacturer's instructions for removal and installation. Always test the linkage for smooth operation after replacement.Q: Why is my throttle cable linkage sticking on my go kart?

A: A sticking throttle cable linkage may be caused by dirt, rust, or cable fraying. Lubricating or replacing the cable often solves the problem. Regular cleaning and inspection help prevent this issue.-

Clutch Line: Braided, Leak-Proof, OEM-Grade PerformanceNewsNov.10,2025

-

Throttle Cable: Durable, Smooth Control & Universal FitNewsNov.10,2025

-

Throttle Cable: Durable, Smooth, Universal Fit, Easy InstallNewsNov.10,2025

-

Clutch Line: Durable, Leak-Proof, OEM-Grade PerformanceNewsNov.10,2025

-

Hand Brake Cable | Custom, Universal & Trailer SolutionsNewsNov.10,2025

-

Clutch Line: High-Pressure, OEM-Fit, Corrosion-ResistantNewsNov.03,2025