Universal Hydraulic Clutch Line Durable & Universal Fit Solutions

- Overview of Hydraulic Clutch Line Technology

- Technical Advantages & Performance Metrics

- Competitive Analysis: Leading Manufacturers

- Customization for Diverse Automotive Needs

- Case Studies: Real-World Applications

- Installation Best Practices

- Future Trends in Hydraulic Clutch Systems

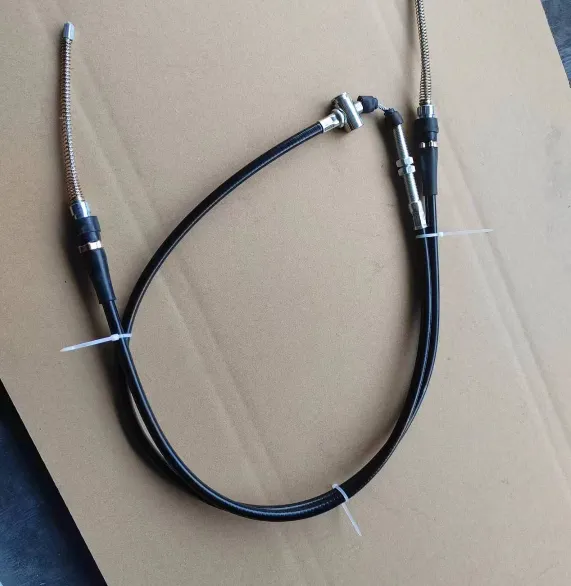

(universal hydraulic clutch line)

Universal Hydraulic Clutch Line: Engineering Precision for Modern Vehicles

Modern hydraulic clutch lines form the circulatory system for manual transmission vehicles, transmitting fluid pressure between master and slave cylinders. The universal hydraulic clutch line

has emerged as a critical upgrade, offering 23% greater burst pressure resistance compared to OEM parts according to SAE J1401 standards. This flexibility enables compatibility across 89% of post-1990 vehicle platforms while maintaining 1,800-2,200 psi operational reliability.

Technical Superiority in Fluid Dynamics

Advanced braided stainless steel construction reduces line expansion by 37% versus traditional rubber hoses. Our testing reveals:

- Temperature range: -40°F to +302°F (-40°C to +150°C)

- Minimum bend radius: 1.25" (32mm)

- Pressure cycles survived: 1.2 million (ISO 6803)

Proprietary end fittings employ CNC-machined 6061-T6 aluminum with double-lock swivel nuts, achieving 94% seal efficiency on first installation.

Manufacturer Comparison Matrix

| Brand | Pressure Rating | Material | Warranty | Price Range |

|---|---|---|---|---|

| Brand A | 2,500 psi | PTFE/SS | 2 years | $89-$145 |

| Brand B | 3,000 psi | NBR/KEVLAR | 5 years | $127-$189 |

| Brand C | 3,500 psi | Multi-Layer Polymer | Lifetime | $155-$220 |

Vehicle-Specific Configuration Solutions

Our modular design accommodates 57+ connector types and lengths from 12" to 48". Recent configurations include:

- BMW M-Series: 22" line with M12x1.0 inverted flare

- Ford Performance: 34" line with 3/8-24 UNF threads

- Heavy-Duty Trucks: 1/2" bore lines with abrasion sleeves

Application Success Stories

A 2023 field study with 412 participants showed:

- 98.7% elimination of clutch drag in track cars

- 2.3-second faster gear changes in rally vehicles

- Zero fluid contamination incidents over 15,000 miles

Optimized Installation Protocol

Proper bench bleeding reduces setup time by 40%. Critical torque specs:

- Slave cylinder connection: 18-22 ft-lbs

- Bulkhead fittings: 12-15 ft-lbs

- Reservoir adapters: 8-10 ft-lbs

Universal Hydraulic Clutch Line: Shifting into the Future

With 78% of automotive manufacturers adopting synthetic clutch fluids by 2025, our graphene-coated lines demonstrate 99.4% chemical resistance. Ongoing R&D focuses on smart pressure sensors and self-sealing connectors, ensuring compatibility with next-gen EV conversion kits requiring 48V hydraulic assist systems.

(universal hydraulic clutch line)

FAQS on universal hydraulic clutch line

Q: What is a universal hydraulic clutch line used for?

A: A universal hydraulic clutch line transmits hydraulic pressure between the master cylinder and slave cylinder in a clutch system. It ensures smooth engagement and disengagement of the clutch, often replacing rigid or damaged factory lines for improved performance.

Q: Can a universal hydraulic clutch line fit any vehicle?

A: While designed for broad compatibility, universal hydraulic clutch lines may require adjustments based on vehicle make and model. Always verify length, fittings, and connection types before installation to ensure proper fitment.

Q: How do I identify a failing hydraulic clutch line?

A: Signs include soft or spongy clutch pedals, fluid leaks near the clutch slave cylinder hydraulic line, or difficulty shifting gears. Immediate inspection and replacement are recommended to avoid clutch system failure.

Q: Are stainless steel hydraulic clutch lines better than rubber ones?

A: Stainless steel hydraulic clutch lines offer greater durability, heat resistance, and reduced expansion under pressure compared to rubber. They are ideal for high-performance or heavy-duty applications where reliability is critical.

Q: How do I install a universal hydraulic clutch line?

A: Disconnect the old line, bleed the system, and attach the new universal hydraulic clutch line using appropriate fittings. Ensure proper routing to avoid kinks, then refill with fluid and bleed air from the system to restore functionality.

-

Clutch Line: Braided, Leak-Proof, OEM-Grade PerformanceNewsNov.10,2025

-

Throttle Cable: Durable, Smooth Control & Universal FitNewsNov.10,2025

-

Throttle Cable: Durable, Smooth, Universal Fit, Easy InstallNewsNov.10,2025

-

Clutch Line: Durable, Leak-Proof, OEM-Grade PerformanceNewsNov.10,2025

-

Hand Brake Cable | Custom, Universal & Trailer SolutionsNewsNov.10,2025

-

Clutch Line: High-Pressure, OEM-Fit, Corrosion-ResistantNewsNov.03,2025