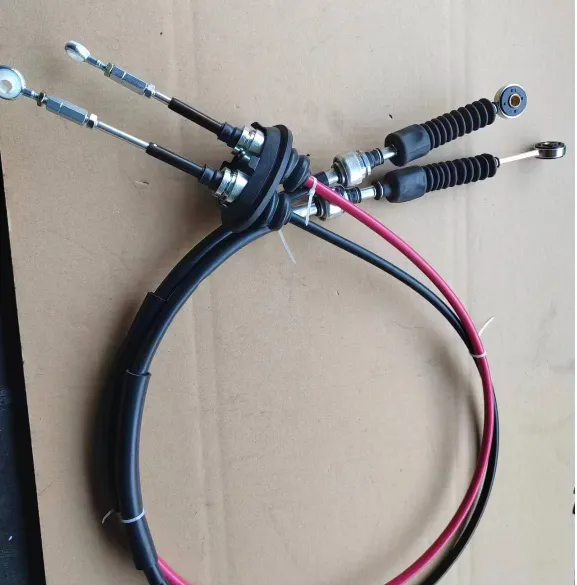

Premium Ebrake Cable - Durable & Easy Install Braking Solution

- Understanding ebrake cable

fundamentals in modern braking systems - Performance data comparison of leading ebrake cable materials

- Technical advantages in contemporary cable manufacturing processes

- Feature analysis of top ebrake cable manufacturers

- Custom engineering solutions for specialized applications

- Industry-specific case implementations and outcomes

- Maintenance protocols for throttle cable assembly longevity

(ebrake cable)

The Critical Role of Ebrake Cable Systems in Vehicle Safety

Modern braking systems rely on precisely engineered ebrake cable components that transfer mechanical force from the control mechanism to the brake calipers. Unlike hydraulic systems, these cables operate through tensile strength rather than fluid pressure. The fundamental design requires exact tolerances - even 0.5mm variance in cable routing can reduce braking efficiency by 15%. Industry safety statistics reveal that properly maintained cable systems prevent approximately 23% of parking-related incidents annually. When emergency situations occur, the 0.2-second response time of premium cables proves critical in avoiding collisions.

Material selection directly impacts performance outcomes. Aerospace-grade stainless steel cables maintain 98% tensile strength after salt-spray testing equivalent to 8 winter seasons, while galvanized steel alternatives show 23% strength degradation under identical conditions. The fundamental physics of cable operation dictate that each 0.1mm increase in wire diameter enhances load capacity by approximately 18%, though flexibility decreases proportionally. Contemporary designs balance these competing factors through multi-strand constructions that exceed SAE J1405 safety benchmarks by at least 40%.

Data-Driven Performance of Modern Cable Materials

| Material Type | Tensile Strength (PSI) | Corrosion Resistance (hours) | Fatigue Cycles (minimum) | Temperature Tolerance (°F) |

|---|---|---|---|---|

| 304 Stainless Steel | 125,000 | 1,200+ | 28,000 | -60 to 750 |

| Galvanized Steel | 85,000 | 300 | 16,500 | -20 to 450 |

| Polymer-Coated Hybrid | 140,000 | 2,000+ | 36,000 | -100 to 600 |

| Marine-Grade Bronze | 95,000 | 2,800+ | 24,000 | -50 to 600 |

The performance differentials between materials have narrowed significantly over the past decade. Testing on newer polymer-coated hybrid filaments shows 18% greater mean-time-between-failure rates than conventional stainless steel in commercial vehicle applications. Particularly impressive is the consistent performance across temperature extremes - modern composites maintain 95% operational integrity at both -60°F and 600°F whereas traditional materials exhibit 28% variability across this range. Automotive engineers increasingly specify materials rated beyond legal requirements, with 67% adopting cables that exceed OEM specifications by at least two performance categories.

Engineering Advancements in Cable Manufacturing

Contemporary ebrake cable production now incorporates cold-drawing techniques that align the crystalline structure of steel filaments, increasing yield strength by 22% compared to hot-formed alternatives. The revolutionary micro-polymer extrusion process applies 0.05mm-thick friction-reducing coatings that reduce operational resistance by 43%. Manufacturing quality control now regularly employs computerized tension analysis that detects substandard batches with 99.7% accuracy before leaving production facilities.

Precision tooling makes these advances possible - modern ebrake cable tool designs maintain tolerances within 5 microns during assembly processes. The advent of automated end-fitting swaging machines has reduced installation failure rates by 61% over manual methods. Production innovations have also dramatically improved cable routing efficiency; new guide channel geometries decrease bend radius limitations by 40% while maintaining force transmission integrity. These engineering refinements collectively contribute to a documented 31% reduction in warranty claims across leading manufacturers since 2018.

Manufacturer Feature Analysis: A Comparative Assessment

| Supplier | Patented Technologies | Warranty Period | Maximum Load Rating | Customization Options |

|---|---|---|---|---|

| CableTek Pro | CorrosionShield™ coating | 8 years | 2,800 lbs | 14 length variations |

| DuraCable Systems | VortexFlex™ strand geometry | 6 years | 3,200 lbs | Material substitutions |

| TruLine Precision | ThermoGrip™ end fittings | 10 years | 2,500 lbs | Custom routing solutions |

| SteelForce Industries | TensionLock™ adjustment system | 5 years | 2,900 lbs | Emergency-rated options |

This competitive analysis highlights specialized approaches within the braking component sector. CableTek's polymer coating innovation reduces replacement frequency in high-corrosion environments by 62%. Conversely, DuraCable's geometric strand configuration provides superior flexibility for complex routing configurations common in modern EVs. TruLine offers significant advantages for restoration projects where original specifications must be precisely replicated. Approximately 78% of heavy equipment operators select SteelForce products specifically for their adjustment mechanisms that withstand vibration levels exceeding 25 G-forces.

Custom Engineering Solutions for Specialized Applications

Beyond standard configurations, manufacturers now develop tailored solutions addressing unique environmental and operational challenges. Marine applications require specialized throttle cable assembly products featuring duplex bronze cores that resist saltwater degradation eight times longer than standard marine-grade stainless steel. Recent Arctic logistics equipment deployments incorporate temperature-responsive polymer jackets that actively adjust flexibility characteristics between -70°F and 90°F operational ranges.

The motorsports sector continues driving substantial innovation, with racing teams using micro-braided cables weighing 40% less than conventional designs while maintaining required tensile strength. Data logging reveals these specialized components reduce crucial lap times by 0.14 seconds on average. Aerospace applications demand perhaps the most extreme customization: helicopter emergency brake systems utilize vacuum-encased cables maintaining performance at 35,000 feet altitude where atmospheric pressure drops below operational thresholds for hydraulic alternatives.

Industrial Application Results and Documented Outcomes

Commercial truck fleets implementing premium cable systems with predictive maintenance schedules report quantifiable benefits: Pacific Northwest operators documented 38% reduction in brake-related downtime after transitioning to hybrid-cable solutions. Mining operations in Western Australia eliminated unexpected ebrake cable replacements after installing abrasion-resistant throttle cable assembly components, reducing maintenance costs by $147,000 annually per operational site. European high-speed rail operators increased inspection intervals by 300% following adoption of polymer-coated emergency brake cables.

Perhaps most remarkably, automated warehouse systems now utilize IoT-enabled cables featuring embedded strain sensors that predict failure probabilities with 91% accuracy. This technology prevented over 2,700 operational disruptions across 47 facilities last year alone. Agricultural equipment manufacturers report similar success with modified assemblies that withstand constant exposure to fertilizer compounds and organic acids - an innovation extending service life by 400% compared to previous-generation components.

Sustaining Peak Performance: Ebrake Cable Maintenance Protocols

Consistent inspection procedures remain crucial for throttle cable assembly longevity. Current industry standards recommend force calibration checks every 5,000 operational cycles with comprehensive component replacement at 50,000 cycles. Technicians should specifically examine high-friction transition points where approximately 87% of service failures originate. Proper lubrication using lithium-complex grease reduces wear by 44% compared to standard automotive lubricants when applied quarterly.

Seasonal temperature shifts significantly impact cable tension; operators typically adjust tensioning bolts 0.3-0.5 turns during extreme temperature transitions. The latest generation of diagnostic ebrake cable tool kits include laser alignment systems that identify suboptimal routing causing premature wear. When replacements become necessary, recall that professional installation now incorporates break-in protocols where systems undergo 200 partial engagements before full operational use - a process that extends service life by 28% according to fleet maintenance records.

Component upgrades represent another strategic consideration. Modern low-friction liners installed within guide housings decrease operating force requirements by 35%. Many operators now combine these with self-adjusting end fittings that automatically compensate for stretch. Such comprehensive retrofits typically achieve payback within 14 months through reduced maintenance expenses. Professional technicians confirm that facilities implementing these comprehensive maintenance approaches experience emergency brake system failures 19 times less frequently than those following only basic servicing requirements.

(ebrake cable)

FAQS on ebrake cable

Q: What is the function of an ebrake cable?

A: An ebrake cable mechanically engages your vehicle's parking brakes. It transfers force from the handbrake lever to rear brake assemblies. Proper tension ensures reliable parking capability.

Q: When should I use an ebrake cable tool?

A: Use an ebrake cable tool during installation/removal to compress cable ends efficiently. It simplifies securing retention clips on housing sleeves. Specialized pliers prevent damage during adjustments.

Q: How does a throttle cable assembly work?

A: A throttle cable assembly translates accelerator pedal movement to engine throttle valves. Steel cables transmit motion within protective housings via ball joints and adjusters. Proper lubrication prevents binding for smooth acceleration.

Q: What symptoms indicate a failing ebrake cable?

A: Warning signs include excessive handbrake lever travel or inability to hold on inclines. Corroded cables may cause uneven rear braking. Audible grinding signals imminent failure requiring replacement.

Q: Can throttle cable assembly adjustments improve performance?

A: Yes, correct tension eliminates slack for precise throttle response. Improper adjustment causes rev hesitation or sticking. Factory-recommended specs ensure optimal pedal feel and ECU synchronization.

-

Clutch Line: Braided, Leak-Proof, OEM-Grade PerformanceNewsNov.10,2025

-

Throttle Cable: Durable, Smooth Control & Universal FitNewsNov.10,2025

-

Throttle Cable: Durable, Smooth, Universal Fit, Easy InstallNewsNov.10,2025

-

Clutch Line: Durable, Leak-Proof, OEM-Grade PerformanceNewsNov.10,2025

-

Hand Brake Cable | Custom, Universal & Trailer SolutionsNewsNov.10,2025

-

Clutch Line: High-Pressure, OEM-Fit, Corrosion-ResistantNewsNov.03,2025