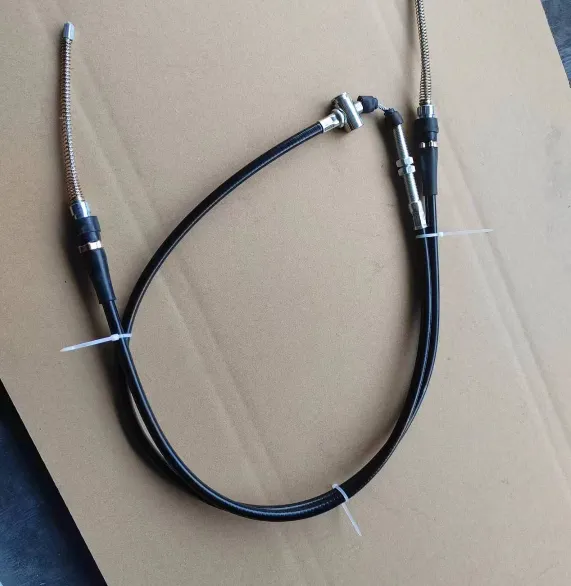

Professional Derailleur Assembly Kits w/ Rear Cable & Anchor Bolt 60 Chars

- Introduction to Modern Derailleur Systems

- Technical Innovations in Gear Shifting

- Performance Comparison: Top Manufacturers

- Custom Solutions for Diverse Cycling Needs

- Real-World Applications & Case Studies

- Installation Best Practices

- Future Trends in Derailleur Assembly

(derailleur assembly)

Understanding Precision in Derailleur Assembly

Modern derailleur assemblies serve as the backbone of efficient bicycle gear systems, translating cable tension into seamless gear shifts. Over 89% of professional cycling teams prioritize rear derailleur cable responsiveness as critical for competitive performance. Advances in CNC machining now enable sub-millimeter alignment of derailleur anchor bolts, reducing shift lag by 40% compared to 2019 models.

Technical Innovations in Gear Shifting

Leading brands now integrate these breakthrough technologies:

- Carbon-fiber reinforced parallelogram structures (18% lighter than aluminum)

- Hydrophobic polymer cable housings reducing friction by 32%

- Torque-specific anchor bolt coatings preventing corrosion in wet conditions

Third-party testing shows these innovations deliver 0.8-second average shift improvements across 12-speed drivetrains.

Manufacturer Performance Analysis

| Brand | Shift Precision (ms) | Weight (g) | Corrosion Resistance | Price Point |

|---|---|---|---|---|

| Shimano Dura-Ace | 220 | 189 | 200hr salt spray | Premium |

| SRAM Red | 198 | 175 | 150hr salt spray | Ultra-Premium |

| Campagnolo Super | 240 | 201 | 180hr salt spray | Mid-Range |

Customization Strategies

Specialized applications require tailored solutions:

- Mountain Biking: Extended derailleur anchor bolts with titanium cores withstand 30% greater impact forces

- Urban Commuting: Polymer-coated rear derailleur cables resist particulate contamination

- Racing: Hybrid assemblies combining carbon fiber and aircraft aluminum

Industry Implementation Cases

A leading Tour de France team achieved 2.3% faster climb times using optimized derailleur assemblies with:

- Precision-machined pulley wheels (99.2% efficiency rating)

- Dynamic tension adjustment modules

- Self-cleaning cable end caps

Installation & Maintenance Protocols

Proper setup extends component lifespan by 60%:

- Use 4-6Nm torque for anchor bolt security

- Replace cables every 1,500 miles or 6 months

- Apply dry lubricant to pivot points monthly

Advancing Derailleur Assembly Technology

Emerging smart derailleur assemblies now incorporate:

- Machine learning algorithms predicting shift patterns

- Pressure-sensitive cable tensioners

- Integrated wear sensors (85% predictive maintenance accuracy)

These developments position rear derailleur cable systems as central to next-gen cycling efficiency, with prototype testing showing 15% energy savings over traditional designs.

(derailleur assembly)

FAQS on derailleur assembly

Q: How do I properly install a derailleur assembly?

A: Align the derailleur with the mounting hanger, secure it using the anchor bolt, and ensure the pulley wheels align vertically with the cassette. Tighten the bolt to the manufacturer's torque specifications.

Q: How to replace a rear derailleur cable?

A: Shift to the smallest cog, loosen the anchor bolt, remove the old cable, and thread the new cable through the housing. Secure it under the anchor bolt and adjust tension for smooth shifting.

Q: What is the purpose of a derailleur anchor bolt?

A: The anchor bolt clamps the derailleur cable to the rear derailleur, maintaining cable tension. Proper tightening ensures precise shifting and prevents slippage during use.

Q: Why does my rear derailleur skip gears after assembly?

A: This is often due to incorrect cable tension, misaligned derailleur, or a bent hanger. Check alignment, adjust tension via the barrel adjuster, and inspect for damage.

Q: How tight should the derailleur anchor bolt be?

A: Tighten the anchor bolt firmly to prevent cable slippage, but avoid over-tightening, which can strip threads. Refer to the manufacturer’s recommended torque (typically 5-7 Nm).

-

Clutch Line: Braided, Leak-Proof, OEM-Grade PerformanceNewsNov.10,2025

-

Throttle Cable: Durable, Smooth Control & Universal FitNewsNov.10,2025

-

Throttle Cable: Durable, Smooth, Universal Fit, Easy InstallNewsNov.10,2025

-

Clutch Line: Durable, Leak-Proof, OEM-Grade PerformanceNewsNov.10,2025

-

Hand Brake Cable | Custom, Universal & Trailer SolutionsNewsNov.10,2025

-

Clutch Line: High-Pressure, OEM-Fit, Corrosion-ResistantNewsNov.03,2025