Januari . 19, 2025 00:43

Back to list

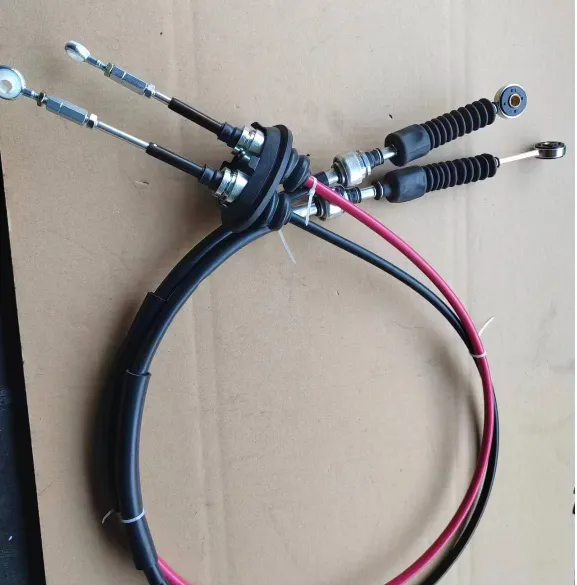

carburetor cable

A carburetor cable, often overlooked but crucial, plays a fundamental role in a vehicle's engine performance. Without it, the engine's response to the throttle would be compromised, leading to inefficient fuel consumption, sluggish acceleration, or even engine stalling. This article delves into the nuanced world of carburetor cables, offering insights from seasoned experts and experienced automotive technicians who understand their pivotal role.

One common recommendation that surfaces through authoritative sources and dedicated automotive forums is the regular lubrication of carburetor cables. Using appropriate lubricants can prevent rust, reduce friction, and extend the lifespan of the cable significantly. This practice is routinely endorsed by automotive experts and is often included in preventive maintenance checklists. Moreover, for those who prefer a hands-on approach to vehicle maintenance, understanding how to adjust a carburetor cable can be empowering. Such adjustments typically involve tightening or loosening the cable to ensure the throttle plate opens fully when the pedal is pressed. This ensures responsive acceleration and efficient engine performance. Resources like detailed automotive repair manuals and instructional videos often serve as valuable tools for enthusiasts who wish to master this skill. Trustworthy mechanics and experienced automotive writers also stress the importance of addressing any unusual symptoms related to carburetor cables swiftly. Signs like spongy throttle response, hesitation during acceleration, or a noticeable loss of power can all be indicative of cable issues. Prompt attention to these symptoms can prevent costly repairs and ensure the vehicle operates at peak performance. In conclusion, the carburetor cable serves as an essential component in the harmonious functioning of an engine. Its understated presence belies its significance. Through a combination of expertise, regular maintenance, and attention to detail, one can ensure this vital cable continues to perform its function effectively, enhancing the driving experience and ensuring vehicle longevity. Understanding and appreciating the role of the carburetor cable not only embodies mechanical expertise but also builds authority and trust within the automotive community.

One common recommendation that surfaces through authoritative sources and dedicated automotive forums is the regular lubrication of carburetor cables. Using appropriate lubricants can prevent rust, reduce friction, and extend the lifespan of the cable significantly. This practice is routinely endorsed by automotive experts and is often included in preventive maintenance checklists. Moreover, for those who prefer a hands-on approach to vehicle maintenance, understanding how to adjust a carburetor cable can be empowering. Such adjustments typically involve tightening or loosening the cable to ensure the throttle plate opens fully when the pedal is pressed. This ensures responsive acceleration and efficient engine performance. Resources like detailed automotive repair manuals and instructional videos often serve as valuable tools for enthusiasts who wish to master this skill. Trustworthy mechanics and experienced automotive writers also stress the importance of addressing any unusual symptoms related to carburetor cables swiftly. Signs like spongy throttle response, hesitation during acceleration, or a noticeable loss of power can all be indicative of cable issues. Prompt attention to these symptoms can prevent costly repairs and ensure the vehicle operates at peak performance. In conclusion, the carburetor cable serves as an essential component in the harmonious functioning of an engine. Its understated presence belies its significance. Through a combination of expertise, regular maintenance, and attention to detail, one can ensure this vital cable continues to perform its function effectively, enhancing the driving experience and ensuring vehicle longevity. Understanding and appreciating the role of the carburetor cable not only embodies mechanical expertise but also builds authority and trust within the automotive community.

Next:

Latest news

-

Upgrade Your Clutch System with Premium Hydraulic Clutch LinesNewsJul.31,2025

-

Unlock the Power of Precision with Our Throttle CablesNewsJul.31,2025

-

Unleash Power and Precision with Our Accelerator CablesNewsJul.31,2025

-

Experience Unmatched Safety with Premium Handbrake CablesNewsJul.31,2025

-

Enhance Your Vehicle's Performance with Quality Gear CablesNewsJul.31,2025

-

Workings of Clutch Pipe and Hose SystemsNewsJun.04,2025