throttle cable manufacturers

Understanding Throttle Cable Manufacturers A Key Player in Automotive Performance

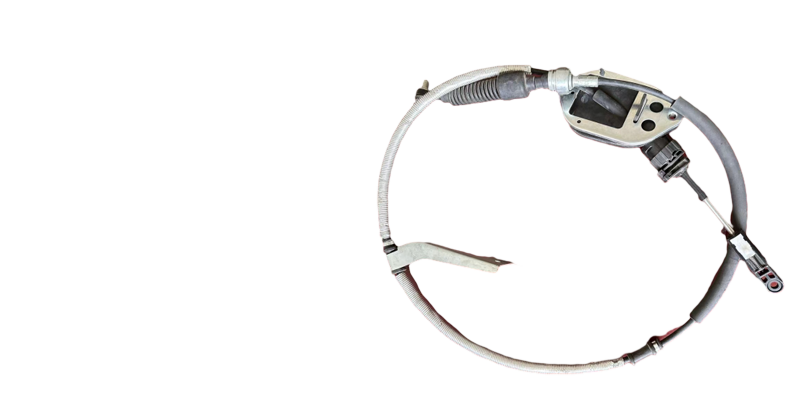

Throttle cables play a pivotal role in the performance and responsiveness of vehicles, serving as the essential link between the accelerator pedal and the engine's throttle body. Manufacturers of throttle cables are crucial in ensuring that these components are not only functional but also reliable and durable. As the automotive industry continues to evolve with advancements in technology, the demand for high-quality throttle cables, alongside an increased focus on performance and safety, puts throttle cable manufacturers at the forefront of engineering innovation.

The Importance of Throttle Cables

Throttle cables are critical for controlling engine power. When a driver presses the accelerator pedal, the throttle cable transmits this input to the engine, allowing it to increase RPM and, subsequently, speed. The quality and precision of the throttle cable influence engine responsiveness and overall driving experience. A faulty cable can lead to delayed throttle response, which can compromise safety and performance. As a result, the importance of selecting and manufacturing high-performance throttle cables cannot be overstated.

Key Features of Quality Throttle Cables

The best throttle cable manufacturers focus on several important features to ensure their products meet the highest standards. These include

1. Durability Throttle cables must withstand extreme temperatures, mechanical stress, and environmental factors. Quality manufacturers use high-grade materials, such as stainless steel or nylon, which resist wear and corrosion.

2. Precision Engineering Tolerances in manufacturing are critical. A well-designed throttle cable should allow for smooth and accurate movements without any binding or slack. This precision is crucial for maintaining proper throttle response at various speeds.

3. Compatibility With a wide range of vehicle makes and models, throttle cable manufacturers often offer a diverse range of products to suit specific applications. This compatibility ensures that car owners can find a suitable replacement that fits perfectly within their vehicle's design.

4. Testing and Quality Control Reputable manufacturers implement rigorous testing protocols to ensure their throttle cables meet or exceed industry standards. This includes stress tests, elongation tests, and environmental resistance assessments to guarantee long-term reliability.

throttle cable manufacturers

The Role of Technology

As technology continues to advance, throttle cable manufacturers are adopting newer methods and materials to enhance their products. The shift towards electronic throttle control (ETC) systems is one notable trend. These systems eliminate the need for a physical cable by using sensors and actuators, allowing for more precise control over engine performance. While the demand for traditional throttle cables may decline due to these advancements, manufacturers are adapting by developing hybrid systems and improving the design of existing cables to meet modern standards.

Environmental Considerations

In today’s world, environmental sustainability is a key focus for many industries, including automotive manufacturing. Throttle cable manufacturers are increasingly looking for ways to reduce waste and the environmental impact of their production processes. This includes using recyclable materials, reducing emissions during manufacturing, and implementing eco-friendly packaging solutions. By doing so, manufacturers not only comply with regulations but also appeal to a growing segment of environmentally conscious consumers.

Market Dynamics and Challenges

While the market for throttle cables remains robust, manufacturers face challenges, including fluctuations in raw material costs and increasing competition from global suppliers. To remain competitive, manufacturers must invest in research and development, focus on customer service, and maintain efficient production processes.

Furthermore, as vehicles become more complex, manufacturers need to stay abreast of the latest automotive technologies to ensure their products are relevant. This adaptability is key in maintaining market share and fulfilling the evolving needs of the automotive industry.

Conclusion

Throttle cable manufacturers are vital players in the automotive sector, contributing significantly to vehicle performance and safety. A commitment to quality, innovation, and sustainability will define the future of this industry. As technology advances and market demands shift, those at the forefront of throttle cable manufacturing will not only survive but thrive by continually adapting to new challenges and opportunities in a competitive landscape. Ultimately, the focus on high-quality throttle cables will enhance the driving experience for consumers and solidify their importance in the automotive parts supply chain.

-

Upgrade Your Control with Premium Throttle CablesNewsAug.08,2025

-

Stay in Control with Premium Hand Brake CablesNewsAug.08,2025

-

Experience Unmatched Performance with Our Clutch HosesNewsAug.08,2025

-

Ensure Safety and Reliability with Premium Handbrake CablesNewsAug.08,2025

-

Enhance Your Vehicle with High-Performance Clutch LinesNewsAug.08,2025

-

Elevate Your Ride with Premium Gear CablesNewsAug.08,2025