handbrake cable makers

The Essential Role of Handbrake Cable Manufacturers in Automotive Safety

In the intricate world of automotive engineering, safety is paramount. Among the many components that contribute to a vehicle's safety, the handbrake cable plays a vital role, acting as a key element in the braking system. As such, handbrake cable manufacturers occupy a crucial niche in the automotive industry, providing essential components that ensure vehicles can stop and park safely.

Understanding Handbrake Cables

Handbrake cables, often referred to as parking brake cables, are responsible for engaging the handbrake, which is primarily a mechanical brake system activated by a lever. This system is crucial for securing vehicles in place when parked, particularly on slopes or uneven terrain. Furthermore, in the event of primary brake failure, handbrake systems act as a secondary measure to help slow down or stop the vehicle, making their reliability vital.

The basic structure of a handbrake cable consists of a steel wire core encased in a protective sheath made of high-strength materials designed to withstand environmental factors. The cable must be flexible enough to allow for smooth operation while being robust enough to endure the strains and stresses of regular use.

The Manufacturing Process

The manufacturing of handbrake cables involves precise engineering and strict quality control. Manufacturers must use high-quality materials to ensure that cables can handle various stresses without fraying or snapping. The process begins with selecting the appropriate materials, typically high-carbon steel for the core to provide the necessary strength, and durable synthetic materials for the sheath to protect against wear and corrosion.

Once the materials are chosen, the cables are cut to specified lengths and constructed with attention to detail. Manufacturers must ensure that the cable is not only functional but also meets automotive industry standards, which often require rigorous testing for durability and safety. Quality assurance measures include tensile tests to ensure that the cables can withstand the forces they will encounter during operation.

The Importance of Standards and Compliance

handbrake cable makers

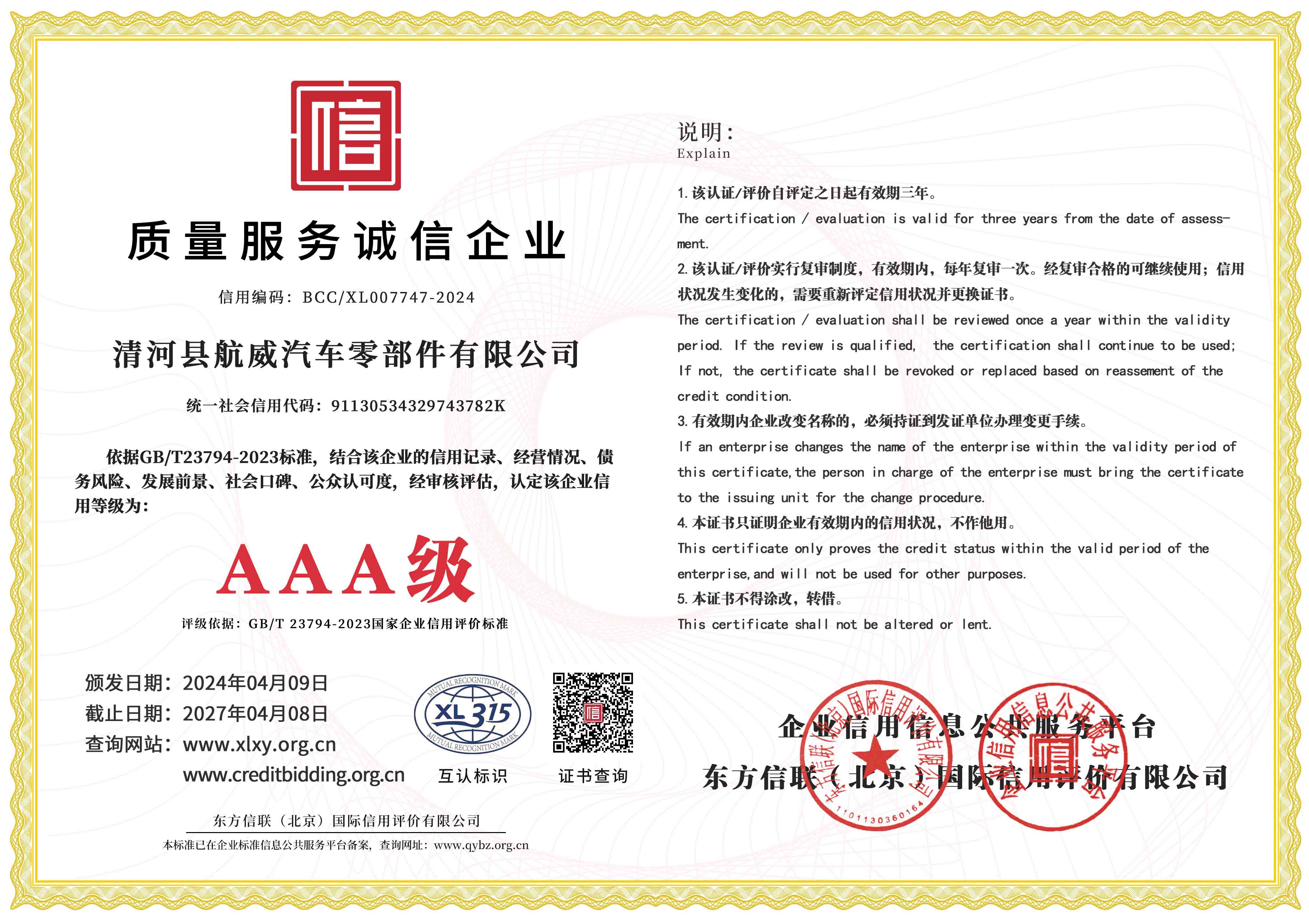

Handbrake cable manufacturers must comply with various industry standards, including those set by the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO). Compliance with these standards ensures that the products meet safety and performance requirements. Companies often seek certifications from these organizations to assure consumers of their product quality.

Moreover, handbrake cables are subject to rigorous testing that evaluates their performance under different conditions. These tests simulate environmental factors such as temperature changes, humidity, and exposure to road salt, which can all affect cable integrity over time. Such thorough testing is essential to ensure that the cables function effectively throughout their lifespan.

Innovations in Handbrake Cable Technology

In recent years, the automotive industry has seen significant advancements in handbrake cable technology. Manufacturers are now exploring innovative materials and designs to enhance performance. For example, some companies are developing corrosion-resistant coatings that increase the lifespan of the cable, even in harsh environmental conditions. Others are investigating the use of lightweight materials that reduce the overall weight of the vehicle, thereby improving fuel efficiency.

Additionally, as vehicles evolve towards automation and electrification, manufacturers are adapting their products accordingly. The integration of electronic handbrake systems, which require different types of cables and mechanisms, is becoming more common. Manufacturers in this space are focusing on producing cables that seamlessly integrate with these new systems while maintaining the reliability that drivers expect.

The Future of Handbrake Cable Manufacturing

Looking ahead, the role of handbrake cable manufacturers will continue to evolve, particularly as the automotive industry shifts towards sustainability and electric vehicles. As environmental concerns take center stage, manufacturers will likely seek to minimize their carbon footprint by adopting greener practices and materials.

In conclusion, handbrake cable manufacturers are essential players in the automotive industry, ensuring that vehicles can be parked securely and providing additional safety features in emergency situations. By maintaining high standards of quality and embracing innovation, these manufacturers will continue to contribute significantly to automotive safety and performance in the years to come. As consumers, understanding the importance of these components can encourage us to prioritize vehicle maintenance and safety features, ultimately ensuring a safer driving experience for everyone.

-

Upgrade Your Control with Premium Throttle CablesNewsAug.08,2025

-

Stay in Control with Premium Hand Brake CablesNewsAug.08,2025

-

Experience Unmatched Performance with Our Clutch HosesNewsAug.08,2025

-

Ensure Safety and Reliability with Premium Handbrake CablesNewsAug.08,2025

-

Enhance Your Vehicle with High-Performance Clutch LinesNewsAug.08,2025

-

Elevate Your Ride with Premium Gear CablesNewsAug.08,2025