Understanding the Functionality and Maintenance of Master Cylinder Clutch Lines in Vehicles

Understanding the Master Cylinder Clutch Line A Crucial Component in Vehicle Performance

The master cylinder clutch line is an integral part of a vehicle's hydraulic clutch system, playing a critical role in the operation and performance of manual transmission cars

. Understanding how this component works, its importance, and the maintenance it requires can greatly enhance a driver's experience and the longevity of their vehicle.At its core, the master cylinder is a hydraulic actuator that translates the driver's input from the clutch pedal into hydraulic pressure. When the driver presses the clutch pedal, the master cylinder, filled with hydraulic fluid, generates pressure that travels through the clutch line to the slave cylinder. This hydraulic pressure then engages or disengages the clutch, allowing smooth shifting between gears without stalling the engine.

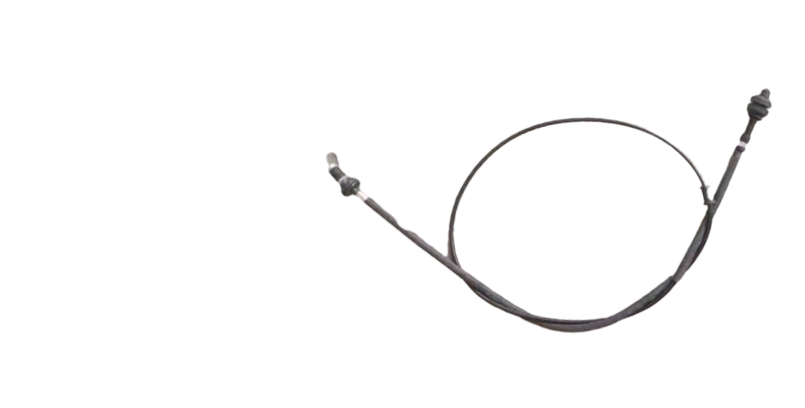

The clutch line, typically made of rubber or metal, serves as the conduit for hydraulic fluid between the master cylinder and the slave cylinder. The integrity of this line is vital, as any leaks or blockages can compromise the entire system's functionality. A compromised clutch line can lead to a range of issues, from difficulty in shifting gears to complete clutch failure, which can leave a driver stranded.

master cylinder clutch line

One of the most notable advantages of a hydraulic clutch system, and by extension, the master cylinder clutch line, is the reduction of physical effort required to operate the clutch. Unlike traditional mechanical clutch systems that rely on cables and springs, hydraulic systems allow for a lighter touch on the clutch pedal. This is particularly beneficial in heavy traffic conditions, where constant gear shifting can lead to driver fatigue.

However, despite the benefits, there are certain challenges associated with hydraulic systems that drivers need to be aware of. One common issue is the potential for air to enter the hydraulic system, which can lead to a spongy clutch pedal and diminished responsiveness. Regular maintenance of the master cylinder and clutch line, including checking for fluid levels and bleeding the system to remove air bubbles, is essential for optimal performance.

The materials used in the construction of the master cylinder and clutch line are also factors that can affect their longevity and performance. For example, rubber lines are more susceptible to wear and deterioration over time due to exposure to heat and pressure, while metal lines can resist these stresses better but may be prone to corrosion if not adequately protected.

In conclusion, the master cylinder clutch line is a crucial element of the hydraulic clutch system in a manual transmission vehicle. Its role in transferring hydraulic pressure from the master cylinder to the slave cylinder highlights the importance of maintaining this system for safe and efficient driving. Routine inspections and maintenance can prevent common problems and ensure that drivers enjoy a smooth and reliable driving experience. Understanding this component allows not only for improved vehicle performance but also enhances a driver’s knowledge of their vehicle, contributing to better overall automotive care. Whether you are a seasoned mechanic or a daily driver, recognizing the importance of the master cylinder clutch line can lead to enhanced safety and driving pleasure on the road.

-

Workings of Clutch Pipe and Hose SystemsNewsJun.04,2025

-

The Inner Workings of Hand Brake Cable SystemsNewsJun.04,2025

-

The Secrets of Throttle and Accelerator CablesNewsJun.04,2025

-

The Hidden Lifeline of Your Transmission Gear Shift CablesNewsJun.04,2025

-

Demystifying Gear Cables and Shift LinkagesNewsJun.04,2025

-

Decoding Clutch Line Systems A Comprehensive GuideNewsJun.04,2025