Understanding the Functionality and Maintenance of Lawn Mower Throttle Cables for Optimal Performance

Understanding Lawn Mower Throttle Cables A Comprehensive Guide

A lawn mower is an essential tool for maintaining a well-manicured yard, and one of the critical components of this machine is the throttle cable. The throttle cable plays a vital role in controlling the engine speed and, subsequently, the mower's cutting performance. Understanding the function, maintenance, and possible issues related to the throttle cable can enhance your mowing experience and prolong the life of your equipment.

What is a Throttle Cable?

The throttle cable is a flexible wire cable that connects the throttle control (usually a lever or handle on the mower) to the carburetor or engine's throttle plate. When you pull the throttle lever, the cable allows the throttle plate to open and close, regulating the amount of air and fuel mixture entering the engine. This control is essential for adjusting the mower's speed, allowing you to mow different types of grass and terrain effectively.

Importance of Proper Throttle Cable Functioning

A well-functioning throttle cable is crucial for optimal performance. When the cable is operating correctly, it ensures that the mower can achieve the desired engine speed efficiently. This not only improves cutting performance but also impacts fuel efficiency and engine health. An improperly functioning throttle can lead to reduced power, difficulty starting the engine, or erratic engine speeds, which can be frustrating for users.

Common Issues with Throttle Cables

Several problems can arise with throttle cables over time. One of the most common issues is fraying or damage to the cable. This can occur due to wear and tear from regular use or exposure to harsh weather conditions. A frayed cable may not transmit the throttle control effectively, leading to inconsistent engine speeds.

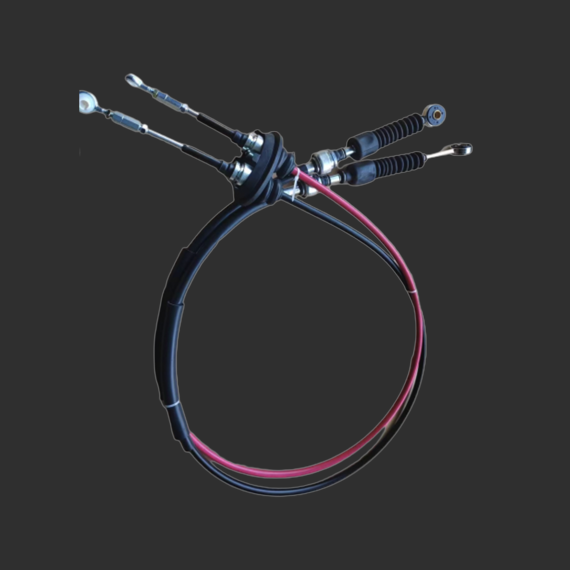

lawn mower throttle cable

Another issue is the potential for the cable to become stuck or bound within its housing. Dirt, debris, or rust can accumulate within the cable's pathway, preventing smooth movement. A stuck cable can limit your ability to control the mower's power output, which can be particularly dangerous if the mower suddenly accelerates or loses power.

Lastly, incorrect cable tension can affect performance. If the cable is too loose, it may not engage the throttle when needed; if it’s too tight, it can put excessive strain on the components, leading to premature wear.

Maintenance Tips

To ensure your lawn mower's throttle cable operates effectively, regular maintenance is essential. Start by inspecting the cable periodically for signs of wear, fraying, or damage. If you notice any issues, it’s advisable to replace the cable promptly to avoid further problems.

Keep the cable and its housing clean. Remove any debris or dirt that may have collected around the throttle mechanism. Additionally, lubricating the cable can help reduce friction and prevent binding. Use a light machine oil and apply it sparingly along the cable to maintain smooth operation.

Conclusion

A lawn mower's throttle cable, while often overlooked, is an integral part of the machine's overall performance. Understanding its function and maintaining it properly can enhance your mowing experience and extend the life of your mower. By being proactive about cable maintenance and addressing any issues promptly, users can enjoy a more efficient, effective, and enjoyable lawn care routine. Remember, a little attention to detail can go a long way in keeping your equipment in top shape, making yard work a breeze rather than a chore.

-

Workings of Clutch Pipe and Hose SystemsNewsJun.04,2025

-

The Inner Workings of Hand Brake Cable SystemsNewsJun.04,2025

-

The Secrets of Throttle and Accelerator CablesNewsJun.04,2025

-

The Hidden Lifeline of Your Transmission Gear Shift CablesNewsJun.04,2025

-

Demystifying Gear Cables and Shift LinkagesNewsJun.04,2025

-

Decoding Clutch Line Systems A Comprehensive GuideNewsJun.04,2025