Top Manufacturers and Suppliers of High-Performance Throttle Cables for Automotive Applications

The Role of Throttle Cable Manufacturers in the Automotive Industry

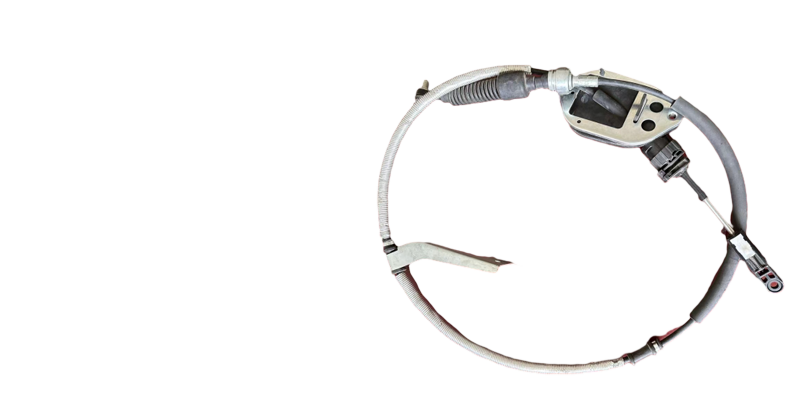

In the intricate world of automotive engineering, throttle cables play a pivotal role in controlling the engine's power output. These cables connect the accelerator pedal to the throttle body, enabling drivers to modulate speed and performance. As the demand for high-performance vehicles continues to rise, the role of throttle cable manufacturers becomes increasingly critical.

Throttle cable manufacturers specialize in producing these essential components to meet diverse automotive needs. Their expertise lies in understanding the dynamics of throttle control and the various materials and designs that optimize performance, durability, and responsiveness. The manufacturing process often involves high-quality raw materials like stainless steel, which provides resistance to corrosion, and various polymers that ensure flexibility and robustness.

One of the key challenges faced by throttle cable manufacturers is ensuring precision in the manufacturing process. Even the slightest deviation in length or calibration can lead to significant performance issues, making it imperative for manufacturers to adhere to strict quality control and testing standards. Advanced technology, including computer numerical control (CNC) machines and automated assembly lines, has revolutionized the industry, allowing for consistent production of high-quality cables.

Moreover, the rise of electric and hybrid vehicles has introduced new dynamics to throttle cable design. Many modern vehicles utilize electronic throttle control (ETC) systems that replace traditional cables with sensors and electronic signals. However, despite the growing prevalence of ETC systems, mechanical throttle cables are still favored in various applications due to their simplicity and reliability. As a result, throttle cable manufacturers must remain adaptable, developing products that cater to both traditional mechanical systems and modern electronic configurations.

throttle cable manufacturers

The global automotive market is also becoming increasingly competitive, pushing manufacturers to innovate and improve their products continually. Research and development play a crucial role in this process, with manufacturers investing in exploring new materials and technologies that enhance performance. For instance, some manufacturers are now exploring lightweight materials to reduce overall vehicle weight while maintaining strength and durability. This innovation not only improves fuel efficiency but also enhances vehicle handling and performance.

Sustainability is another critical focus area for throttle cable manufacturers. With an increasing emphasis on eco-friendliness in the automotive industry, manufacturers are looking for ways to reduce their environmental footprint. This includes sourcing materials from sustainable suppliers, implementing energy-efficient manufacturing processes, and even developing recyclable throttle cables.

Collaboration with automotive manufacturers is also vital for throttle cable manufacturers. By working closely with vehicle designers and engineers, these manufacturers can ensure that their products are tailored to meet specific performance requirements. Such partnerships often lead to co-development projects, where manufacturers can leverage their expertise to help automotive companies achieve their goals.

As the automotive industry continues to evolve, the importance of throttle cable manufacturers cannot be overstated. Their ability to produce high-quality, precise, and innovative products is essential for ensuring the performance and reliability of vehicles on the road. With advancements in technology, materials science, and sustainability practices, these manufacturers are well-equipped to meet the challenges of a rapidly changing market.

In conclusion, throttle cable manufacturers play a crucial role in the automotive industry, contributing to the performance and safety of vehicles. Their commitment to quality, innovation, and sustainability will not only shape the future of throttle control systems but also influence the broader landscape of automotive engineering. As the industry evolves, these manufacturers will continue to be integral players in driving progress and enhancing the driving experience for consumers worldwide.

-

Upgrade Your Control with Premium Throttle CablesNewsAug.08,2025

-

Stay in Control with Premium Hand Brake CablesNewsAug.08,2025

-

Experience Unmatched Performance with Our Clutch HosesNewsAug.08,2025

-

Ensure Safety and Reliability with Premium Handbrake CablesNewsAug.08,2025

-

Enhance Your Vehicle with High-Performance Clutch LinesNewsAug.08,2025

-

Elevate Your Ride with Premium Gear CablesNewsAug.08,2025