throttle cable manufacturers

Understanding Throttle Cable Manufacturers and Their Importance

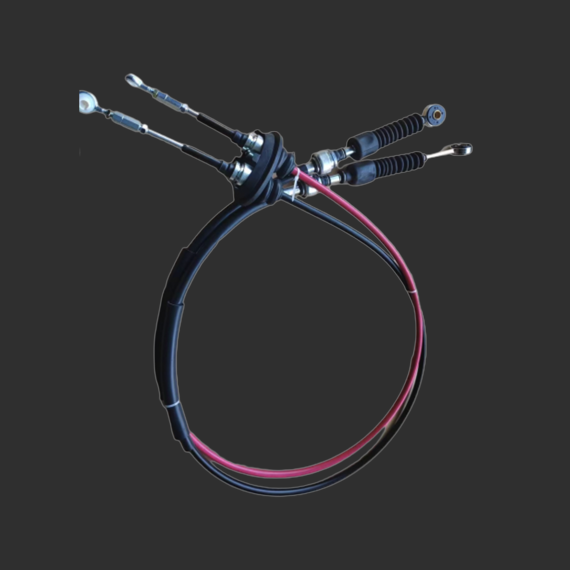

Throttle cables play a critical role in the automotive and machinery industries, serving as the vital link between the accelerator pedal and the engine. This seemingly simple component is responsible for regulating the engine's power output by controlling air and fuel intake. Given its importance, the quality and reliability of throttle cables are paramount, making the choice of manufacturer crucial for vehicle performance and safety.

Throttle cable manufacturers are tasked with producing cables that not only meet stringent safety standards but also perform consistently under various conditions. These cables must be durable, resistant to wear and tear, and capable of withstanding extreme temperatures. As such, manufacturers often utilize high-grade materials, including stainless steel, nylon, and other composites, to ensure that their products can endure the rigors of daily use.

The manufacturing process of throttle cables involves a combination of precision engineering and innovative design. Companies invest in advanced machinery and technology to ensure that each cable is produced with exact tolerances. This precision is vital, as even minor discrepancies in cable length or construction can lead to performance issues or, worse, catastrophic failures.

In addition to maintaining high manufacturing standards, reputable throttle cable manufacturers often engage in rigorous quality control processes. This includes extensive testing of their products under simulated real-world conditions. By subjecting their cables to extensive stress tests, manufacturers can identify potential weaknesses and make necessary improvements before the products reach the market.

throttle cable manufacturers

Moreover, the landscape of throttle cable manufacturing has evolved with advancements in technology. The rise of automation and computer-aided design (CAD) has revolutionized production efficiency, enabling manufacturers to create intricate designs and streamline their assembly processes. As a result, consumers benefit from more reliable products that are often available at competitive prices.

Another important aspect of throttle cable manufacturers is their commitment to customer service and support. Many companies offer customization options to cater to specific vehicle models or customer preferences. This level of service not only enhances customer satisfaction but also builds long-term relationships between manufacturers and their clients.

In the auto aftermarket industry, the demand for high-quality throttle cables is ever-growing. As vehicles age, components such as throttle cables may require replacement. Established manufacturers often provide comprehensive catalogs of replacement parts, ensuring that customers can find the right solution for their needs swiftly.

In conclusion, throttle cable manufacturers play an indispensable role in the automotive and machinery sectors by producing components that are critical for engine performance and safety. The combination of advanced manufacturing techniques, stringent quality control measures, innovative materials, and responsive customer service ensures that these manufacturers meet the evolving demands of consumers and the industry at large. As technology continues to advance, we can expect even greater improvements in throttle cable design and manufacturing, ultimately contributing to better-performing and safer vehicles on the roads.

-

Workings of Clutch Pipe and Hose SystemsNewsJun.04,2025

-

The Inner Workings of Hand Brake Cable SystemsNewsJun.04,2025

-

The Secrets of Throttle and Accelerator CablesNewsJun.04,2025

-

The Hidden Lifeline of Your Transmission Gear Shift CablesNewsJun.04,2025

-

Demystifying Gear Cables and Shift LinkagesNewsJun.04,2025

-

Decoding Clutch Line Systems A Comprehensive GuideNewsJun.04,2025