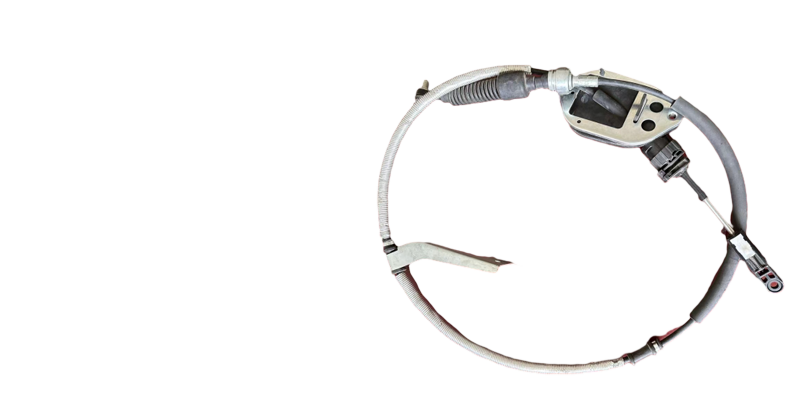

steel clutch line

The Essential Role of Steel Clutch Lines in Automotive Performance

In the world of automotive engineering, every component plays a vital role in ensuring the seamless operation of a vehicle. Among these components, the clutch line often goes unnoticed, yet it is crucial for effective power transfer from the engine to the transmission. When it comes to high-performance vehicles or any application where durability and reliability are paramount, steel clutch lines have emerged as a favored choice among automotive enthusiasts and engineers alike.

Before delving into the specifics of steel clutch lines, it's important to understand their function. The clutch line is responsible for transferring hydraulic fluid from the master cylinder to the slave cylinder in a hydraulic clutch system. This hydraulic action engages and disengages the clutch, allowing drivers to smoothly shift gears. Traditional rubber lines, while functional, have inherent weaknesses such as susceptibility to heat expansion, wear over time, and degradation from exposure to various fluids.

In contrast, steel clutch lines address these issues with a robust design that significantly enhances performance and longevity. One of the primary advantages of using steel is its strength. Steel lines can withstand higher pressures compared to their rubber counterparts, making them ideal for high-performance applications that demand reliable clutch engagement under extreme conditions. This strength also contributes to a more consistent clutch feel, allowing for better driver control and precision during gear shifts.

steel clutch line

Another critical factor is heat resistance. Steel doesn't expand or contract as much as rubber when subjected to temperature fluctuations, which helps maintain hydraulic pressure. This stability is crucial for racing environments where rapid acceleration can generate significant heat. Additionally, steel lines are less prone to swelling, which can lead to inconsistent clutch performance—a common issue seen with aging rubber lines.

Installation of steel clutch lines typically involves a straightforward process, though care must be taken to ensure proper routing and securing to avoid rubbing against other components. Many aftermarket providers offer pre-formed steel lines, making the installation even more accessible for both professional mechanics and DIY enthusiasts.

While the performance benefits of steel clutch lines are evident, they also offer aesthetic advantages. Many car enthusiasts take pride in showcasing their vehicle's engine bay, and the sleek, polished appearance of stainless steel lines can enhance the overall look of the engine compartment.

In conclusion, the integration of steel clutch lines in automotive design represents a significant advancement in enhancing vehicle performance and reliability. Their strength, heat resistance, and consistent performance make them an excellent choice for anyone looking to elevate their driving experience, whether on the street or the racetrack. As automotive technology continues to evolve, steel clutch lines will undoubtedly remain a staple in the push for better performance and durability in vehicles.

-

Workings of Clutch Pipe and Hose SystemsNewsJun.04,2025

-

The Inner Workings of Hand Brake Cable SystemsNewsJun.04,2025

-

The Secrets of Throttle and Accelerator CablesNewsJun.04,2025

-

The Hidden Lifeline of Your Transmission Gear Shift CablesNewsJun.04,2025

-

Demystifying Gear Cables and Shift LinkagesNewsJun.04,2025

-

Decoding Clutch Line Systems A Comprehensive GuideNewsJun.04,2025