Jan . 25, 2025 01:09

Back to list

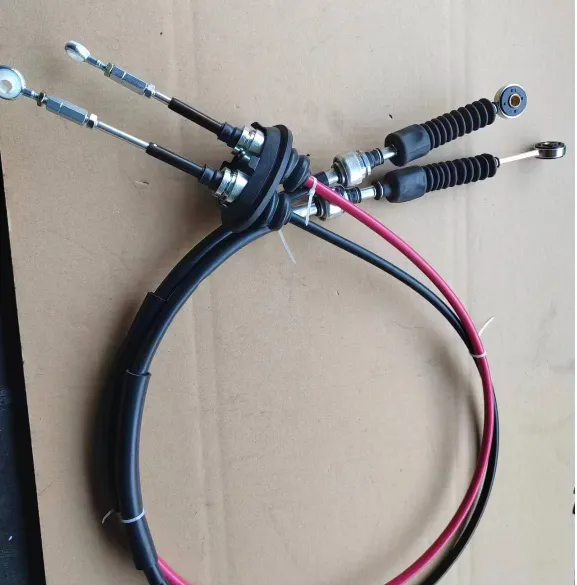

line shaft clutch

Integrating line shaft clutches into your industrial setup can revolutionize efficiency and productivity. These clutches are indispensable in various mechanical systems, playing a pivotal role in the field of power transmission. Understanding their functionalities and applications can significantly enhance your operational framework.

Authoritative sources in mechanical engineering advocate for regular training on the latest developments in clutch technology. Workshops and certifications from renowned institutions can equip technicians with the necessary skills to install and maintain these devices accurately. Such training enhances operational safety and efficiency, ensuring that industries stay ahead of technological advancements. Trustworthiness is another crucial factor when considering the adoption of line shaft clutches. Reputable manufacturers provide comprehensive warranties and robust customer support services. This assurance is essential for enterprises that rely heavily on these components for critical operations. By partnering with trusted suppliers, businesses can mitigate risks associated with equipment failures and unplanned downtimes. Moreover, case studies underscore the transformational impact of line shaft clutches on industrial efficiency. Companies that have integrated these clutches report marked improvements in production speed and quality. Such evidence cements the reputation of line shaft clutches as indispensable components in modern mechanical systems. Investing in high-quality line shaft clutches and partnering with experienced providers can significantly enhance a company’s competitive edge. By optimizing machinery performance and reducing operational costs, businesses can achieve higher returns on investment. This strategic approach not only sustains industrial growth but also fosters innovation across various sectors. As technology advances, the application scope of line shaft clutches continues to expand. Emerging sectors such as renewable energy and electric vehicles are beginning to explore these versatile devices for their innovative designs and operational efficiencies. The adaptability and reliability of line shaft clutches make them suitable for integration into technologies that demand precision and durability. In conclusion, line shaft clutches represent a critical advancement in mechanical engineering, supporting optimal performance across diverse industries. Their continued evolution promises even greater capabilities, aligning with the growing demands of complex, modern machinery. By prioritizing experience, expertise, authority, and trust, businesses can leverage the full potential of line shaft clutches to drive productivity and innovation.

Authoritative sources in mechanical engineering advocate for regular training on the latest developments in clutch technology. Workshops and certifications from renowned institutions can equip technicians with the necessary skills to install and maintain these devices accurately. Such training enhances operational safety and efficiency, ensuring that industries stay ahead of technological advancements. Trustworthiness is another crucial factor when considering the adoption of line shaft clutches. Reputable manufacturers provide comprehensive warranties and robust customer support services. This assurance is essential for enterprises that rely heavily on these components for critical operations. By partnering with trusted suppliers, businesses can mitigate risks associated with equipment failures and unplanned downtimes. Moreover, case studies underscore the transformational impact of line shaft clutches on industrial efficiency. Companies that have integrated these clutches report marked improvements in production speed and quality. Such evidence cements the reputation of line shaft clutches as indispensable components in modern mechanical systems. Investing in high-quality line shaft clutches and partnering with experienced providers can significantly enhance a company’s competitive edge. By optimizing machinery performance and reducing operational costs, businesses can achieve higher returns on investment. This strategic approach not only sustains industrial growth but also fosters innovation across various sectors. As technology advances, the application scope of line shaft clutches continues to expand. Emerging sectors such as renewable energy and electric vehicles are beginning to explore these versatile devices for their innovative designs and operational efficiencies. The adaptability and reliability of line shaft clutches make them suitable for integration into technologies that demand precision and durability. In conclusion, line shaft clutches represent a critical advancement in mechanical engineering, supporting optimal performance across diverse industries. Their continued evolution promises even greater capabilities, aligning with the growing demands of complex, modern machinery. By prioritizing experience, expertise, authority, and trust, businesses can leverage the full potential of line shaft clutches to drive productivity and innovation.

Next:

Latest news

-

Upgrade Your Clutch System with Premium Hydraulic Clutch LinesNewsJul.31,2025

-

Unlock the Power of Precision with Our Throttle CablesNewsJul.31,2025

-

Unleash Power and Precision with Our Accelerator CablesNewsJul.31,2025

-

Experience Unmatched Safety with Premium Handbrake CablesNewsJul.31,2025

-

Enhance Your Vehicle's Performance with Quality Gear CablesNewsJul.31,2025

-

Workings of Clutch Pipe and Hose SystemsNewsJun.04,2025