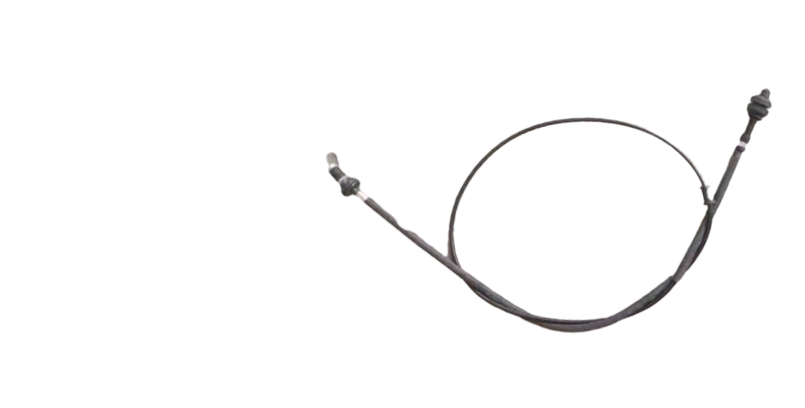

in line clutch

The Significance of In-Line Clutches in Modern Machinery

In the realm of engineering and machinery, the term in-line clutch refers to a specific type of mechanical device that plays a crucial role in the functioning of various machines and systems. As technologies advance and the demand for efficient power transfer continues to grow, the in-line clutch has emerged as an essential component in numerous applications, including automotive, aerospace, robotics, and industrial machinery.

An in-line clutch is essentially a mechanism that allows for the connection and disconnection of power between two shafts or components. It is designed to engage and disengage smoothly, which enables operators to control the operation of machinery effectively. The positioning of the clutch in a straight line – hence the name in-line – is significant because it minimizes the complexity of design while maximizing efficiency. This straightforward configuration allows for more compact designs, making it suitable for applications where space is limited.

The Significance of In-Line Clutches in Modern Machinery

In the automotive industry, in-line clutches are primarily found in manual transmissions and certain automatic systems. They allow drivers to smoothly shift gears, connecting and disconnecting the engine from the wheels as required. This feature is particularly important for performance vehicles, where precise control over power delivery can significantly impact acceleration and overall driving experience. Additionally, the development of electric vehicles has led to increased integration of in-line clutches in these systems, enabling seamless transitions between various power sources.

in line clutch

The aerospace sector also benefits greatly from in-line clutches. Aircraft rely on numerous interconnected systems, and the ability to isolate different sections of the aircraft during operation is vital for safety. In-line clutches contribute to this safety by enabling controlled disengagement of systems without compromising the entire operation. For example, if one engine's power needs to be reduced or shut off, an in-line clutch can facilitate this process seamlessly, allowing other systems to function without disruption.

In the field of robotics, in-line clutches are essential in providing precise control over movement and force transmission. Many robotic systems require the ability to start and stop rapidly, engage and disengage different tools, or alter the path of motion dynamically. The responsiveness and reliability of in-line clutches make them an integral part of modern robotic designs, enhancing their versatility and functionality.

Moreover, advancements in materials and manufacturing techniques have led to the development of improved in-line clutches that are lighter, stronger, and more efficient than ever before. The incorporation of smart technologies and sensors has further refined their operation, allowing for real-time monitoring and adjustments based on operational demands.

In conclusion, the in-line clutch stands as a pivotal component across various industries, serving as a bridge between power sources and machinery. Its ability to engage and disengage smoothly not only enhances operational efficiency but also provides safety and reliability in demanding environments. As technology continues to evolve, the role of in-line clutches will undoubtedly expand, ensuring their place at the forefront of modern machinery and engineering innovation.

-

Upgrade Your Control with Premium Throttle CablesNewsAug.08,2025

-

Stay in Control with Premium Hand Brake CablesNewsAug.08,2025

-

Experience Unmatched Performance with Our Clutch HosesNewsAug.08,2025

-

Ensure Safety and Reliability with Premium Handbrake CablesNewsAug.08,2025

-

Enhance Your Vehicle with High-Performance Clutch LinesNewsAug.08,2025

-

Elevate Your Ride with Premium Gear CablesNewsAug.08,2025