Jun . 21, 2024 12:23

Back to list

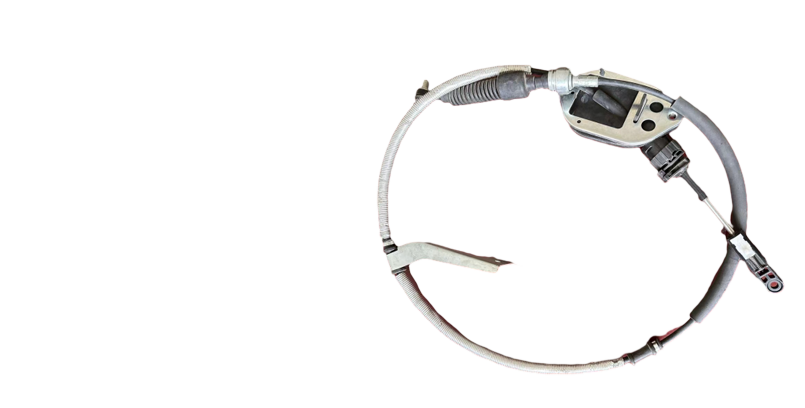

Implementing the line shaft clutch engagement mechanism.

The Significance and Function of Line Shaft Clutches in Industrial Machinery

A Line Shaft Clutch, a vital component in traditional industrial machinery, plays an indispensable role in the transmission and control of mechanical power. This technology, dating back to the era of industrial revolution, has evolved significantly over time, adapting to the changing demands of modern manufacturing processes.

The concept of a line shaft, also known as a power shaft, is rooted in the early days of mechanization when factories were powered by a central water wheel or steam engine. The power from these sources was transmitted through a series of interconnected shafts and pulleys, with the line shaft clutch serving as the mediator for engagement and disengagement of various machines along the line. This system allowed for the efficient distribution of power across different workstations, significantly increasing productivity.

A line shaft clutch, fundamentally, is a mechanical device designed to connect or disconnect two rotating shafts. It enables the operator to selectively engage or disengage the power flow, thereby controlling the operation of the machinery connected to the line shaft. The clutch typically consists of two parts - a driving member and a driven member - that can be joined or separated depending on the need. When engaged, the driving member transfers torque to the driven member, while in the disengaged state, it allows the shafts to rotate independently.

The clutch's functionality is not limited to power transmission alone

The clutch's functionality is not limited to power transmission alone The clutch's functionality is not limited to power transmission alone

The clutch's functionality is not limited to power transmission alone

The clutch's functionality is not limited to power transmission alone

The clutch's functionality is not limited to power transmission alone line shaft clutch. It also serves as a safety mechanism, preventing damage to the machinery in case of overload or malfunction. By isolating individual machines, a line shaft clutch can minimize the risk of cascading failures, which could otherwise lead to significant downtime and repair costs.

Over the years, with advancements in technology, line shaft systems have given way to more direct drive and individual motor-driven systems. However, in certain industries, particularly those involving large-scale, continuous production lines, line shaft clutches remain relevant. They are still used in applications where the efficient transfer of power over long distances or between multiple machines is crucial, such as in paper mills,, and some forms of material handling equipment.

In conclusion, the line shaft clutch, despite its seemingly archaic nature, remains an integral part of industrial heritage and continues to contribute to the efficiency and safety of modern manufacturing processes. Its design and function embody the spirit of engineering innovation that has shaped the industrial landscape over centuries. As technology progresses, so does the line shaft clutch, evolving to meet the demands of a changing world while preserving the principles of its past.

line shaft clutch. It also serves as a safety mechanism, preventing damage to the machinery in case of overload or malfunction. By isolating individual machines, a line shaft clutch can minimize the risk of cascading failures, which could otherwise lead to significant downtime and repair costs.

Over the years, with advancements in technology, line shaft systems have given way to more direct drive and individual motor-driven systems. However, in certain industries, particularly those involving large-scale, continuous production lines, line shaft clutches remain relevant. They are still used in applications where the efficient transfer of power over long distances or between multiple machines is crucial, such as in paper mills,, and some forms of material handling equipment.

In conclusion, the line shaft clutch, despite its seemingly archaic nature, remains an integral part of industrial heritage and continues to contribute to the efficiency and safety of modern manufacturing processes. Its design and function embody the spirit of engineering innovation that has shaped the industrial landscape over centuries. As technology progresses, so does the line shaft clutch, evolving to meet the demands of a changing world while preserving the principles of its past.

The clutch's functionality is not limited to power transmission alone

The clutch's functionality is not limited to power transmission alone

The clutch's functionality is not limited to power transmission alone

The clutch's functionality is not limited to power transmission alone line shaft clutch. It also serves as a safety mechanism, preventing damage to the machinery in case of overload or malfunction. By isolating individual machines, a line shaft clutch can minimize the risk of cascading failures, which could otherwise lead to significant downtime and repair costs.

Over the years, with advancements in technology, line shaft systems have given way to more direct drive and individual motor-driven systems. However, in certain industries, particularly those involving large-scale, continuous production lines, line shaft clutches remain relevant. They are still used in applications where the efficient transfer of power over long distances or between multiple machines is crucial, such as in paper mills,, and some forms of material handling equipment.

In conclusion, the line shaft clutch, despite its seemingly archaic nature, remains an integral part of industrial heritage and continues to contribute to the efficiency and safety of modern manufacturing processes. Its design and function embody the spirit of engineering innovation that has shaped the industrial landscape over centuries. As technology progresses, so does the line shaft clutch, evolving to meet the demands of a changing world while preserving the principles of its past.

line shaft clutch. It also serves as a safety mechanism, preventing damage to the machinery in case of overload or malfunction. By isolating individual machines, a line shaft clutch can minimize the risk of cascading failures, which could otherwise lead to significant downtime and repair costs.

Over the years, with advancements in technology, line shaft systems have given way to more direct drive and individual motor-driven systems. However, in certain industries, particularly those involving large-scale, continuous production lines, line shaft clutches remain relevant. They are still used in applications where the efficient transfer of power over long distances or between multiple machines is crucial, such as in paper mills,, and some forms of material handling equipment.

In conclusion, the line shaft clutch, despite its seemingly archaic nature, remains an integral part of industrial heritage and continues to contribute to the efficiency and safety of modern manufacturing processes. Its design and function embody the spirit of engineering innovation that has shaped the industrial landscape over centuries. As technology progresses, so does the line shaft clutch, evolving to meet the demands of a changing world while preserving the principles of its past.

Latest news

-

Workings of Clutch Pipe and Hose SystemsNewsJun.04,2025

-

The Inner Workings of Hand Brake Cable SystemsNewsJun.04,2025

-

The Secrets of Throttle and Accelerator CablesNewsJun.04,2025

-

The Hidden Lifeline of Your Transmission Gear Shift CablesNewsJun.04,2025

-

Demystifying Gear Cables and Shift LinkagesNewsJun.04,2025

-

Decoding Clutch Line Systems A Comprehensive GuideNewsJun.04,2025