High-Performance Clutch Master Cylinder Hose for Improved Vehicle Performance and Durability

Understanding Clutch Master Cylinder Hoses An Essential Component for Vehicle Performance

The clutch system in a vehicle plays a critical role in enabling the driver to engage and disengage the engine from the transmission smoothly. At the heart of this system is the clutch master cylinder, which converts the force applied by the driver's foot into hydraulic pressure that facilitates gear changes. One often overlooked but essential component of this system is the clutch master cylinder hose. In this article, we will explore the importance of this component, the materials used, potential issues that may arise, and maintenance tips to ensure optimal performance.

The Role of the Clutch Master Cylinder Hose

The clutch master cylinder hose acts as a conduit for hydraulic fluid between the master cylinder and the clutch slave cylinder. It plays a pivotal role in transmitting the hydraulic pressure generated by the master cylinder, enabling the slave cylinder to engage and disengage the clutch effectively. Without a functioning hose, the hydraulic pressure would be lost, resulting in a non-operational clutch system that can lead to significant driving difficulties, including the inability to shift gears.

Materials Used in Clutch Master Cylinder Hoses

Clutch master cylinder hoses are typically made from materials designed to withstand high pressures and temperatures. Common materials include rubber and reinforced synthetic compounds. These materials are chosen for their ability to resist fluid leaks, abrasions, and environmental factors such as heat and chemicals. The reinforcement within the hose provides extra strength, ensuring that it can handle the pressure exerted during the clutch operation.

Common Issues with Clutch Master Cylinder Hoses

Like any other component in a vehicle, clutch master cylinder hoses can face wear and tear over time. Common issues include

1. Leaks This is one of the most prevalent problems associated with clutch hoses. A leak can occur due to cracks, abrasions, or aging of the material. A leak in the system can dramatically reduce the hydraulic pressure, leading to clutch failure.

2. Bulging or Swelling Exposure to extreme temperatures or incompatible fluids can lead to the hose bulging or swelling. This condition can obstruct the flow of hydraulic fluid, leading to erratic clutch behavior.

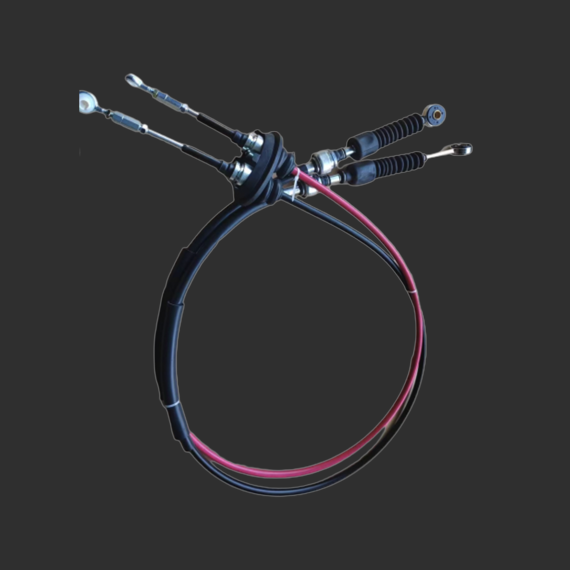

clutch master cylinder hose

3. Blockages Debris or sediment can accumulate within the hose, leading to blockages that interrupt the flow of hydraulic fluid. This can result in poor clutch performance and difficulties in shifting gears.

Maintenance Tips

To ensure the clutch master cylinder hose remains in optimal condition, regular maintenance is essential. Here are some tips

1. Visual Inspections Regularly inspect the hoses for any signs of wear, including cracks, leaks, or bulging. Look for any signs of fluid around the hose, which can indicate a leak.

2. Fluid Checks Regularly check the hydraulic fluid level in the master cylinder reservoir. Low fluid levels may indicate a leak or other issues within the hydraulic system.

3. Replace When Necessary If any signs of wear or damage are present, it is crucial to replace the hose immediately. Delaying replacement can lead to more severe problems and even a complete clutch failure.

4. Use Quality Parts When replacing the hose, always opt for high-quality replacement parts. Cheaper alternatives may save money initially but can result in more frequent replacements and potential failures.

Conclusion

The clutch master cylinder hose is a vital component of a vehicle's clutch system, playing an essential role in the smooth operation of gear changes. By understanding its functions, common issues, and maintenance requirements, vehicle owners can ensure their clutch system remains functional and reliable. Regular inspections and timely replacements will not only enhance vehicle performance but also contribute to safer driving experiences.

-

Upgrade Your Control with Premium Throttle CablesNewsAug.08,2025

-

Stay in Control with Premium Hand Brake CablesNewsAug.08,2025

-

Experience Unmatched Performance with Our Clutch HosesNewsAug.08,2025

-

Ensure Safety and Reliability with Premium Handbrake CablesNewsAug.08,2025

-

Enhance Your Vehicle with High-Performance Clutch LinesNewsAug.08,2025

-

Elevate Your Ride with Premium Gear CablesNewsAug.08,2025