handbrake cable manufacturers

The Importance of Handbrake Cable Manufacturers in Automotive Safety

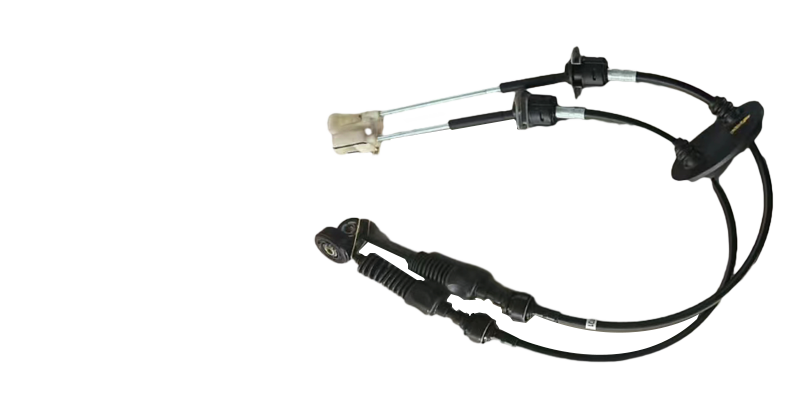

In the automotive industry, safety is paramount. One critical component that plays a significant role in ensuring vehicle safety is the handbrake cable. Often overlooked, this small yet vital component is essential for the proper functioning of the handbrake system. Handbrake cable manufacturers are at the heart of this important safety feature, producing cables that ensure vehicles can be securely parked and prevented from rolling away.

Understanding Handbrake Cables

The handbrake, also known as the parking brake, is a mechanical device that locks the rear wheels of a vehicle when engaged. This is particularly important in preventing rollaways when a car is parked on an incline. The handbrake cable connects the lever inside the vehicle to the brake mechanism on the rear wheels, transmitting the force applied by the driver to engage the brake. Over time, however, these cables can wear out, fray, or corrode, leading to decreased effectiveness or complete failure.

The Role of Manufacturers

Handbrake cable manufacturers are crucial in the production of these components. They utilize high-quality materials and advanced manufacturing processes to ensure that the cables they produce are durable, reliable, and capable of withstanding the rigors of everyday use. Common materials used in the production of handbrake cables include high-carbon steel and PTFE coatings, which offer enhanced resistance to wear and corrosion.

These manufacturers are not only responsible for producing standard cables but also custom solutions tailored to specific vehicle models. With the ever-increasing variety of vehicles on the market, from compact cars to heavy-duty trucks, the demand for specialized handbrake cables has risen. Manufacturers invest in research and development to innovate new designs and improve existing products, ensuring that they meet the diverse needs of automotive manufacturers and consumers.

handbrake cable manufacturers

Quality Control and Safety Standards

Safety is a primary concern for handbrake cable manufacturers. Therefore, stringent quality control measures are integral to the manufacturing process. Manufacturers adhere to international safety standards and often conduct rigorous testing on their products. This includes tensile strength tests, corrosion resistance tests, and performance evaluations to ensure that each cable can handle the stresses of regular use. With the automotive industry placing an increasing emphasis on safety and reliability, manufacturers must ensure that their products comply with regulations set by organizations such as the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO).

The Impact of Technological Advancements

With advancements in technology, handbrake cable manufacturers are leveraging innovative techniques to enhance their production processes. For instance, the use of computer-aided design (CAD) allows for precise engineering of cable components, while automated machinery enables faster production with higher consistency. Additionally, manufacturers are adopting more sustainable practices, such as reducing waste and utilizing environmentally friendly materials, in response to growing concerns about environmental impact.

Future Trends in Handbrake Cable Manufacturing

As the automotive industry evolves, handbrake cable manufacturers must stay ahead of trends. The rise of electric and hybrid vehicles, for instance, presents unique challenges and opportunities in the design of braking systems. Manufacturers are exploring new materials and technologies to ensure that handbrake systems remain effective in these new types of vehicles.

In conclusion, handbrake cable manufacturers play an essential role in the automotive industry's safety landscape. By producing high-quality, reliable cables, they help ensure that vehicles can be parked securely and safely. As the industry continues to evolve, these manufacturers will be pivotal in adapting to new technologies and safety standards, ultimately contributing to the overall safety and reliability of vehicles on the road. Their commitment to quality and innovation is what keeps drivers and passengers safe, reinforcing the importance of their work in the automotive supply chain.

-

Workings of Clutch Pipe and Hose SystemsNewsJun.04,2025

-

The Inner Workings of Hand Brake Cable SystemsNewsJun.04,2025

-

The Secrets of Throttle and Accelerator CablesNewsJun.04,2025

-

The Hidden Lifeline of Your Transmission Gear Shift CablesNewsJun.04,2025

-

Demystifying Gear Cables and Shift LinkagesNewsJun.04,2025

-

Decoding Clutch Line Systems A Comprehensive GuideNewsJun.04,2025