Flexible Hose Pipe for Clutch Systems in Automotive Applications and Performance Upgrades

Understanding Clutch Hose Pipes Importance, Functionality, and Maintenance

In the realm of automotive engineering and maintenance, the clutch hose pipe plays a pivotal role in ensuring the efficient operation of a vehicle's clutch system. This crucial component, often overlooked, facilitates the transfer of hydraulic fluid, enabling the seamless engagement and disengagement of the clutch. In this article, we will explore the importance, functionality, and maintenance of clutch hose pipes, shedding light on an essential element of vehicle performance.

Importance of Clutch Hose Pipes

Clutch hose pipes are integral to the hydraulic clutch system commonly found in modern vehicles. The primary purpose of these hoses is to convey hydraulic pressure from the master cylinder to the slave cylinder, allowing the clutch to function correctly. When the driver presses the clutch pedal, hydraulic fluid is forced into the slave cylinder through the clutch hose pipe. This action engages or disengages the clutch, enabling smooth gear shifts and optimal vehicle control.

A malfunctioning clutch hose pipe can lead to an inability to disengage the clutch, resulting in gear grinding and difficulty in changing gears. In severe cases, a ruptured or damaged hose can lead to fluid leaks, causing a complete failure of the clutch system. Therefore, the integrity of the clutch hose pipe is vital for vehicle safety and performance.

Functionality of Clutch Hose Pipes

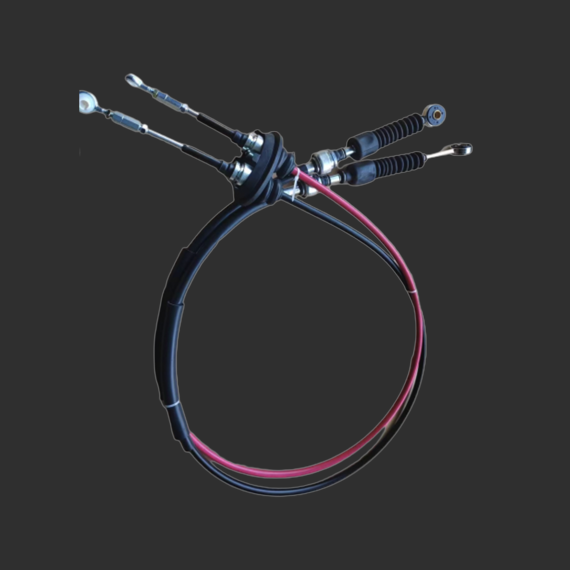

The functionality of clutch hose pipes is primarily associated with their ability to withstand high pressure and temperature variations

. Typically made from reinforced rubber or thermoplastic materials, these hoses are designed to endure the harsh conditions of the automotive environment. The inner lining is often resistant to corrosive hydraulic fluids, ensuring longevity and reliability.Clutch hose pipes are engineered to maintain a consistent diameter and shape, minimizing the risk of expansion or contraction under pressure. This stability allows for efficient fluid transfer, which is crucial for the timely engagement and disengagement of the clutch. Additionally, some hoses are equipped with protective features, such as braided steel sheathing, to prevent abrasion and damage due to external influences.

Maintenance of Clutch Hose Pipes

clutch hose pipe

Regular maintenance of clutch hose pipes is essential for ensuring the long-term functionality of the clutch system. Here are some key maintenance practices

1. Visual Inspection Regularly inspect the clutch hose for any signs of wear, cracks, or leaks. Any visible damage should prompt immediate replacement to avoid further complications.

2. Fluid Check Ensure that the hydraulic fluid level is adequate and that the fluid is in good condition. Contaminated or old fluid can lead to hose degradation and affect clutch performance.

3. Pressure Testing Periodically perform pressure tests on the clutch system to confirm that the hoses and other components can withstand operational pressures without failing.

4. Cleaning Keep the hose and surrounding areas clean to prevent contaminants from compromising the hose material.

5. Professional Inspection Have a qualified mechanic conduct a thorough inspection during routine vehicle maintenance. Professionals can identify potential issues that might be overlooked by the untrained eye.

Conclusion

In summary, the clutch hose pipe is a vital component of a vehicle's clutch system, playing a critical role in the safe and efficient operation of the vehicle. Understanding its importance, functionality, and the necessity of regular maintenance can help drivers ensure their vehicles remain in optimal condition. By taking proactive measures to care for the clutch hose pipes, drivers can enhance the longevity and reliability of their vehicles, ultimately improving driving safety and performance.

-

Upgrade Your Control with Premium Throttle CablesNewsAug.08,2025

-

Stay in Control with Premium Hand Brake CablesNewsAug.08,2025

-

Experience Unmatched Performance with Our Clutch HosesNewsAug.08,2025

-

Ensure Safety and Reliability with Premium Handbrake CablesNewsAug.08,2025

-

Enhance Your Vehicle with High-Performance Clutch LinesNewsAug.08,2025

-

Elevate Your Ride with Premium Gear CablesNewsAug.08,2025