Exploring the Importance of Clutch Hoses in Automotive Performance and Maintenance for Optimal Driving Experience

Understanding Clutch Hoses The Unsung Heroes of Automotive Performance

When it comes to the intricate mechanics of a vehicle, many components work seamlessly together to ensure a smooth driving experience. Among these components, the clutch hose plays a pivotal but often overlooked role. This article explores the significance of clutch hoses, their benefits, types, maintenance, and implications for overall vehicle performance.

What is a Clutch Hose?

A clutch hose is a vital component in hydraulic clutch systems, which are common in manual transmission vehicles. The primary function of the clutch hose is to transport hydraulic fluid from the master cylinder to the slave cylinder. This connection is essential as it enables the proper engagement and disengagement of the clutch. When the driver presses the clutch pedal, the master cylinder generates hydraulic pressure, which is transmitted via the clutch hose to the slave cylinder, effectively releasing the engine's power from the transmission.

Importance of Clutch Hoses

Clutch hoses may seem minor, but they are crucial for the smooth functioning of manual transmissions. A malfunctioning clutch hose can lead to a series of problems, including difficulty in shifting gears, clutch slippage, or even complete failure to disengage the clutch. Such issues can compromise vehicle safety and make driving a challenging experience. Therefore, understanding the importance of a well-functioning clutch hose is essential for every driver.

Types of Clutch Hoses

Clutch hoses come in various types, each designed to meet specific performance standards. The most common types include rubber hoses, braided stainless steel hoses, and PTFE (Teflon) hoses.

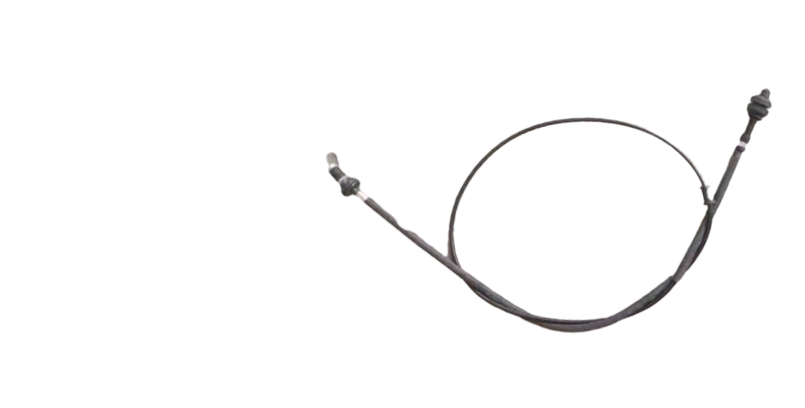

clutch hose

1. Rubber Hoses Traditionally, most vehicles come equipped with rubber clutch hoses. They are cost-effective and offer reasonable performance; however, they can degrade over time due to exposure to heat and contaminants.

2. Braided Stainless Steel Hoses For those seeking improved performance and durability, braided stainless steel hoses are an excellent upgrade. These hoses feature a stainless steel outer layer that enhances strength and resistance to wear and tear. They also provide better pedal feel, which is crucial for performance enthusiasts.

3. PTFE Hoses PTFE hoses provide the highest level of resistance to heat and chemical damage. Their smooth inner lining reduces friction, allowing for quicker response times when engaging or disengaging the clutch. These hoses are ideal for vehicles that undergo extreme performance or racing conditions.

Maintenance and Replacement

Like any vehicle component, clutch hoses require regular maintenance to ensure they function correctly. Drivers should routinely inspect their hoses for signs of wear, such as cracks, bulges, or fluid leaks. If any of these signs are present, it is crucial to replace the hose promptly to prevent further damage to the clutch system.

Moreover, when replacing a clutch hose, it may be advantageous to consider upgrading to a braided stainless steel or PTFE hose for enhanced performance and longevity. Regular fluid changes in the clutch system are also essential, as contaminated fluid can lead to premature wear of both the hose and the entire hydraulic system.

Conclusion

In conclusion, while often relegated to the background, clutch hoses are integral to the functioning of a manual transmission system. Their role in facilitating hydraulic pressure makes them essential for robust vehicle performance. By understanding the importance of clutch hoses and maintaining them properly, drivers can ensure a smoother, safer driving experience. Whether through routine checks or strategic upgrades, paying attention to this often-overlooked component can significantly enhance overall vehicle reliability and performance.

-

Workings of Clutch Pipe and Hose SystemsNewsJun.04,2025

-

The Inner Workings of Hand Brake Cable SystemsNewsJun.04,2025

-

The Secrets of Throttle and Accelerator CablesNewsJun.04,2025

-

The Hidden Lifeline of Your Transmission Gear Shift CablesNewsJun.04,2025

-

Demystifying Gear Cables and Shift LinkagesNewsJun.04,2025

-

Decoding Clutch Line Systems A Comprehensive GuideNewsJun.04,2025