Hydraulic Piping Solutions for Optimal Clutch Performance and Reliability in Vehicles

Understanding Clutch Hydraulic Pipes Function, Design, and Importance

Clutch hydraulic pipes play a crucial role in the operation of hydraulic clutch systems found in modern vehicles. These systems are designed to provide smoother engagement and disengagement of the clutch, enhancing overall driving performance. To fully appreciate the significance of clutch hydraulic pipes, it is essential to understand their function, design, and importance in automotive engineering.

Function of Clutch Hydraulic Pipes

The primary function of the clutch hydraulic pipe is to transport hydraulic fluid between the master cylinder and the slave cylinder. When the driver presses the clutch pedal, this action applies pressure to the hydraulic fluid in the master cylinder. The pressurized fluid is then sent through the hydraulic pipes to the slave cylinder, which activates the clutch mechanism, allowing the driver to shift gears seamlessly.

This system offers several advantages over traditional mechanical linkages. Hydraulic systems can operate with less physical effort from the driver, leading to a more comfortable driving experience. Additionally, they reduce the wear and tear on mechanical components, as hydraulic systems are less prone to slippage and friction-related issues.

Design of Clutch Hydraulic Pipes

Clutch hydraulic pipes are typically constructed from high-pressure-rated materials to withstand the substantial forces generated during clutch operation. They are usually made of reinforced rubber or steel, ensuring durability and resistance to wear. The design must also account for heat dissipation, as hydraulic fluids can become heated during constant use.

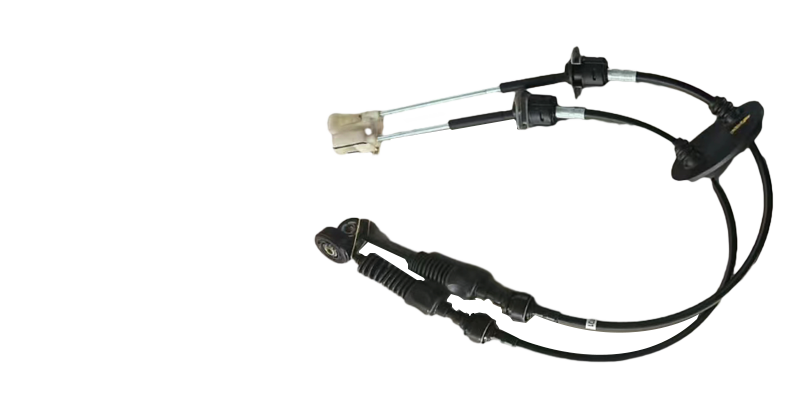

clutch hydraulic pipe

The dimensions of these pipes are critical; they must be of appropriate diameter to allow adequate fluid flow while preventing any potential leaks. Additionally, hydraulic pipes must be resistant to corrosion, which can arise from exposure to various environmental factors and the hydraulic fluid itself. Proper fittings and connections are equally vital to maintain a sealed system, avoiding hydraulic fluid loss that can lead to clutch failure.

Importance of Clutch Hydraulic Pipes

The importance of clutch hydraulic pipes cannot be overstated, as they are integral to the performance and safety of a vehicle. A failure in the hydraulic system, such as a leak in the pipes, can result in a loss of hydraulic pressure, making it impossible to disengage the clutch. This can lead to a dangerous situation where the driver cannot shift gears or control the vehicle effectively.

Regular maintenance of the hydraulic system, including inspection of the clutch hydraulic pipes, is essential to ensure safe operation. Mechanic specialists recommend checking hydraulic fluid levels, inspecting for leaks, and assessing the overall condition of the hydraulic pipes as part of routine vehicle servicing. By addressing minor issues early on, vehicle owners can prevent costly repairs and ensure longevity for their clutch systems.

Conclusion

In conclusion, clutch hydraulic pipes are vital components that enable efficient functioning of hydraulic clutch systems in vehicles. Their ability to transmit hydraulic fluid effectively and withstand high pressures ensures smooth gear shifting, contributing to a better driving experience. Understanding the function, design, and importance of these pipes is essential for both drivers and automotive professionals alike. Regular inspections and maintenance will help preserve the integrity of the hydraulic system, ensuring that vehicles remain safe and efficient on the road for years to come.

Whether you are a casual driver or an automotive enthusiast, knowledge about clutch hydraulic pipes enhances your understanding of how your vehicle operates, enabling informed decisions regarding maintenance and care. In a world where vehicle reliability is paramount, ensuring that each component, however small, functions optimally can make all the difference in achieving peak performance and safety.

-

Workings of Clutch Pipe and Hose SystemsNewsJun.04,2025

-

The Inner Workings of Hand Brake Cable SystemsNewsJun.04,2025

-

The Secrets of Throttle and Accelerator CablesNewsJun.04,2025

-

The Hidden Lifeline of Your Transmission Gear Shift CablesNewsJun.04,2025

-

Demystifying Gear Cables and Shift LinkagesNewsJun.04,2025

-

Decoding Clutch Line Systems A Comprehensive GuideNewsJun.04,2025