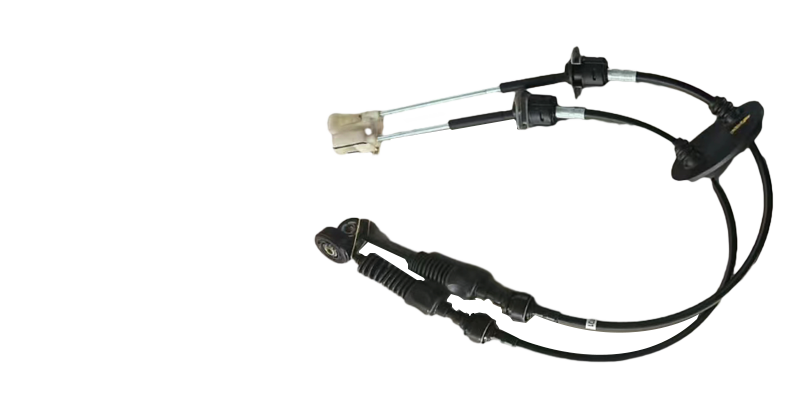

clutch cable assembly

Understanding Clutch Cable Assembly A Comprehensive Overview

Clutch cable assemblies play a critical role in the functioning of manual transmission vehicles, ensuring seamless gear shifts and overall drivability. This essential component connects the clutch pedal to the clutch mechanism, allowing the driver to engage and disengage the engine from the transmission quickly. In this article, we will explore the significance, construction, maintenance, and troubleshooting of clutch cable assemblies.

The Role of Clutch Cable Assembly

At its core, the clutch cable assembly serves as the link between the clutch pedal and the clutch fork, which operates the pressure plate. When the driver presses the clutch pedal, the cable pulls the fork, disengaging the clutch from the engine. This process allows for smooth shifts from one gear to another. The significance of this component cannot be understated; a malfunctioning clutch cable can lead to difficulties in changing gears, which may result in poor vehicle performance or even damage to the transmission.

Construction of Clutch Cable Assembly

A typical clutch cable assembly consists of several key components

1. Cable The main body of the assembly, the cable, is usually made of high-strength steel to withstand the tension and friction involved in the operation. 2. Housing The cable is encased in a protective housing that prevents debris and moisture from affecting its functionality. This housing is often made from durable materials like nylon or metal.

3. End Fittings The assembly features specific end fittings that attach the cable to the clutch pedal and the clutch fork. These fittings must be robust and precisely engineered to ensure proper engagement and disengagement of the clutch.

Maintenance of Clutch Cable Assembly

Proper maintenance of the clutch cable assembly is essential for ensuring long-term vehicle reliability. Here are some key maintenance tips

clutch cable assembly

1. Regular Inspections Drivers should regularly inspect the clutch cable for signs of wear, fraying, or corrosion. This inspection includes checking the cable housing for cracks and ensuring that the end fittings are secure.

2. Lubrication While most clutch cables are designed to be low-maintenance, occasional lubrication may be beneficial. Using a suitable lubricant designed for this purpose can help reduce friction and prevent premature wear.

3. Adjustments Periodic adjustments may be necessary, especially as the vehicle ages. Proper tension ensures that the clutch engages and disengages smoothly, preventing unnecessary strain on the other components.

Troubleshooting Clutch Cable Issues

Even with proper maintenance, clutch cable assemblies can encounter issues that may hinder vehicle performance. Here are common problems and their solutions

1. Stiff Clutch Pedal If the clutch pedal feels excessively stiff, it may indicate that the cable is binding or frayed. Inspection and potential replacement of the cable are necessary.

2. Incomplete Engagement/Disengagement If the clutch is not fully disengaging, the vehicle may grind gears. This issue may stem from a misadjustment in the cable tension or cable wear and should be addressed promptly to avoid transmission damage.

3. Pedal Travel Issues If the clutch pedal does not return to its original position, it may be due to a broken cable or a malfunctioning adjustment mechanism. This situation requires immediate attention to prevent driving issues.

Conclusion

Clutch cable assemblies are vital components of manual transmission systems, directly affecting vehicle performance and driver experience. Understanding their construction, maintenance needs, and potential issues can help drivers ensure their vehicles operate smoothly and reliably. Regular inspections and adherence to maintenance tips will not only enhance performance but also extend the lifespan of the clutch system, ultimately ensuring a safer and more enjoyable driving experience. Whether you are a seasoned mechanic or a novice car owner, recognizing the importance of clutch cable assemblies is crucial in the realm of automotive maintenance.

-

Workings of Clutch Pipe and Hose SystemsNewsJun.04,2025

-

The Inner Workings of Hand Brake Cable SystemsNewsJun.04,2025

-

The Secrets of Throttle and Accelerator CablesNewsJun.04,2025

-

The Hidden Lifeline of Your Transmission Gear Shift CablesNewsJun.04,2025

-

Demystifying Gear Cables and Shift LinkagesNewsJun.04,2025

-

Decoding Clutch Line Systems A Comprehensive GuideNewsJun.04,2025