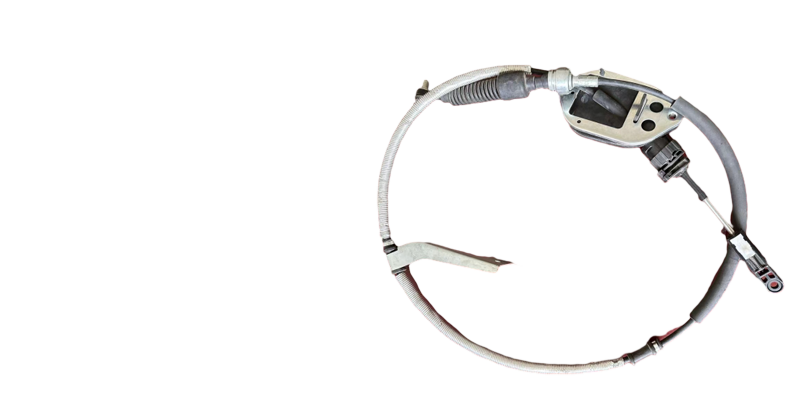

carburetor choke cable

Understanding the Carburetor Choke Cable Function, Importance, and Maintenance

The carburetor choke cable is a crucial component in older vehicles and small engines that rely on carburetors for fuel delivery. While fuel injection systems have largely replaced carburetors in modern automotive designs, understanding the choke cable’s function and maintenance can still be beneficial for enthusiasts, restorers, and those operating classic vehicles or small engines like lawn mowers and chainsaws.

What is a Carburetor Choke?

The purpose of a choke is to regulate the air-to-fuel ratio entering the engine during cold start conditions. When an engine is cold, it requires a richer fuel mixture to start efficiently because the fuel does not vaporize as well as it does at higher temperatures. The carburetor choke enriches the fuel mixture by restricting airflow into the engine, allowing more fuel to be drawn in and providing the necessary enrichment for starting.

The Role of the Choke Cable

The choke cable is the physical link that allows the driver or operator to manually engage or disengage the choke. It connects the choke mechanism in the carburetor to the accelerator or the driver’s dashboard. When the driver pulls the choke cable, it either pushes a lever or pulls a rod that closes the choke valve, reducing airflow into the carburetor. Once the engine is running and reaches a suitable temperature, the choke can be disengaged, allowing for normal operation.

Importance of the Choke Cable

1. Engine Performance A properly functioning choke cable ensures that the engine receives the right amount of fuel during cold starts. This is particularly vital in colder climates where temperatures drop significantly, making cold starts more challenging.

2. Ease of Use Many engines equipped with a manual choke provide operators with more control over the starting process. In situations where the engine may struggle to start, being able to manually engage the choke can make a significant difference.

3. Maintenance Indicator A malfunctioning choke cable can lead to starting issues, rough idling, or poor acceleration. Monitoring the choke cable's functionality serves as an early warning system for possible carburetor issues.

Common Issues with Choke Cables

carburetor choke cable

1. Cable Fraying or Damage Over time, the cable can fray due to wear and tear or environmental factors such as exposure to heat and moisture. Regular checks can help identify frayed cables that need replacement.

2. Sticking or Binding Sometimes the cable can become stuck or fail to operate smoothly due to rust, dirt, or improper routing. This can cause difficulties in adjusting the choke.

3. Misalignment If the choke cable is improperly aligned or if the choke mechanism itself is misaligned, the choke may not close fully or may not open properly. Proper installation and adjustment are essential to ensure optimal functionality.

Maintenance Tips

1. Regular Inspections Check the choke cable for signs of wear, fraying, rust, or other damage. Regular inspections can help catch issues before they result in larger problems.

2. Lubrication If the choke cable does not operate smoothly, a suitable lubricant can be applied. However, care must be taken not to introduce contaminants into the carburetor.

3. Proper Adjustment Ensure the cable is not too tight or too loose. Proper tension is crucial for the choke mechanism to function correctly. Refer to the vehicle's service manual for specific adjustment procedures.

4. Cleaning Keep the surrounding area clean to prevent dirt and debris from interfering with the choke mechanism's operation.

5. Replacement If the choke cable is severely damaged or worn out, replacing it with a new one is often the best course of action. Always use parts that are compatible with your engine’s make and model.

Conclusion

The carburetor choke cable, while often overlooked, plays a significant role in the performance of older vehicles and small engines. Understanding its function, importance, and common issues can help users maintain their vehicles effectively and ensure that they operate smoothly, particularly in cold conditions. With proper maintenance and care, the carburetor choke cable can provide reliable service for many years, enhancing the engine's overall functionality and longevity. For those who love classic cars or maintain small engines for various tasks, familiarity with the choke cable is essential for optimal performance and efficiency.

-

Workings of Clutch Pipe and Hose SystemsNewsJun.04,2025

-

The Inner Workings of Hand Brake Cable SystemsNewsJun.04,2025

-

The Secrets of Throttle and Accelerator CablesNewsJun.04,2025

-

The Hidden Lifeline of Your Transmission Gear Shift CablesNewsJun.04,2025

-

Demystifying Gear Cables and Shift LinkagesNewsJun.04,2025

-

Decoding Clutch Line Systems A Comprehensive GuideNewsJun.04,2025