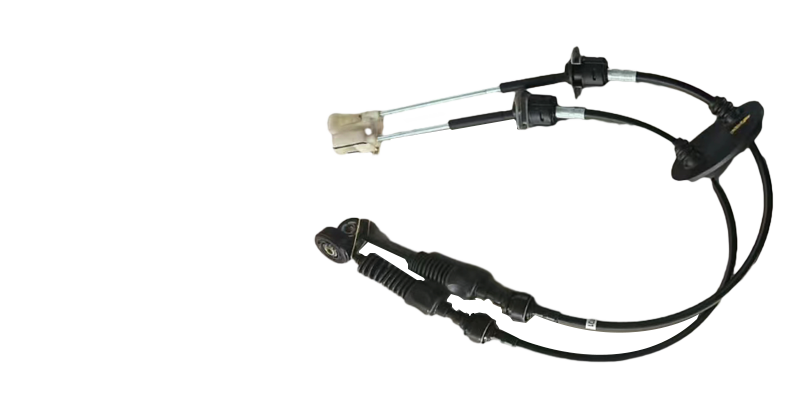

clutch master cylinder line

Understanding the Clutch Master Cylinder Line

In automotive engineering, the clutch master cylinder line is a crucial component in the operation of manual transmission vehicles. Understanding its role can help both car enthusiasts and everyday drivers appreciate the importance of each part in their vehicle and how they contribute to overall functionality.

What is the Clutch Master Cylinder?

The clutch master cylinder is a hydraulic device that converts the mechanical force exerted on the clutch pedal into hydraulic pressure. When a driver depresses the clutch pedal, it pushes a rod that moves a piston inside the master cylinder. This action compresses hydraulic fluid, which is then transferred through the clutch master cylinder line to the slave cylinder, ultimately disengaging the clutch. This process allows the driver to change gears smoothly and effectively.

The Role of the Clutch Master Cylinder Line

The clutch master cylinder line, often referred to simply as the clutch line, is a critical link in this hydraulic system. It is typically constructed from metal or durable rubber materials that can withstand the high pressure generated within the system. The primary function of the clutch master cylinder line is to transport hydraulic fluid from the master cylinder to the slave cylinder.

A well-functioning clutch line ensures that the hydraulic pressure is maintained throughout the system, which is essential for effective clutch operation. If there are any leaks, abrasions, or deterioration in the line, it can lead to a reduction in hydraulic pressure, making it difficult or impossible to disengage the clutch. This can result in poor gear shifting, increased wear on the clutch components, and a potentially dangerous driving situation.

Common Issues with the Clutch Master Cylinder Line

clutch master cylinder line

Like any automotive component, the clutch master cylinder line is subject to wear and tear over time. A few common issues that may arise include

1. Leaks One of the most frequent issues is a leak in the clutch line, which can be caused by wear, corrosion, or improper installation. A leaking line will lead to a loss of hydraulic fluid, causing the clutch to fail. 2. Crimping or Kinking If the clutch line is not properly routed, it may become crimped or kinked, resulting in restricted flow of the hydraulic fluid. This can lead to inadequate engagement or disengagement of the clutch.

3. Corrosion Over time, especially in regions with harsh weather conditions, the clutch line can corrode, especially if it is made of metal. This corrosion can weaken the line, making it susceptible to leaks.

Maintenance and Replacement

Regular maintenance of the clutch system, including the clutch master cylinder line, is essential to prevent potential failures. It's advisable to inspect the line for any signs of wear or damage during routine vehicle maintenance. If any issues are detected, prompt replacement is crucial.

To replace a defective clutch master cylinder line, vehicle owners should consult a professional mechanic or refer to their vehicle’s repair manual. The process typically involves draining the hydraulic fluid, removing the old line, and installing a new one, followed by bleeding the hydraulic system to remove any air bubbles.

Conclusion

The clutch master cylinder line is a vital component in the hydraulic system of manual transmission vehicles. Understanding its function and potential issues can enhance vehicle owners' awareness and maintenance practices. By keeping an eye on the health of this line, drivers can ensure smoother operation of their vehicle’s clutch system, leading to safer and more enjoyable driving experiences.

-

Upgrade Your Control with Premium Throttle CablesNewsAug.08,2025

-

Stay in Control with Premium Hand Brake CablesNewsAug.08,2025

-

Experience Unmatched Performance with Our Clutch HosesNewsAug.08,2025

-

Ensure Safety and Reliability with Premium Handbrake CablesNewsAug.08,2025

-

Enhance Your Vehicle with High-Performance Clutch LinesNewsAug.08,2025

-

Elevate Your Ride with Premium Gear CablesNewsAug.08,2025