កុម្ភៈ . 10, 2025 10:49

Back to list

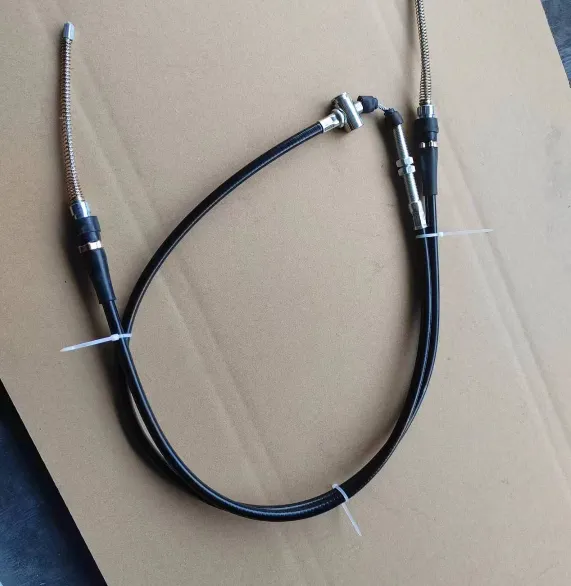

clutch master cylinder line

The Clutch Master Cylinder Line Enhancing Vehicle Performance through Precision Engineering and Optimal Functionality

In terms of expertise, a deep understanding of hydraulic systems is imperative for those involved in designing or maintaining clutch master cylinder lines. Knowledge of fluid dynamics, pressure constants, and material science enables professionals to optimize these lines for varied automotive needs—whether it's a high-performance sports car requiring rapid gear shifts or a heavy-duty truck demanding durability under load. The authoritativeness of brands specializing in clutch master cylinder lines can often be judged by their adherence to industry standards. ISO certification or compliance with SAE standards serves as an indicator of a manufacturer’s commitment to quality and reliability. Brands with a strong history in automotive components often have extensive testing protocols in place to simulate real-world driving conditions, ensuring that their products perform flawlessly under stress. Trustworthiness in the world of automotive parts translates to innovation backed by proven results. Brands focusing on clutch master cylinder lines often build trust by engaging with the automotive community, taking feedback from professional drivers, mechanics, and everyday users. Publishing case studies that document performance improvements, or offering extended warranties, reinforces consumer confidence in their products. Trusted brands also maintain transparency regarding the construction and capabilities of their clutch lines, often providing detailed specifications and compatibility guides to assist with selection and installation. Ultimately, the clutch master cylinder line is a testament to the symbiotic relationship between engineering precision and practical application. This product, while often overlooked, is integral to vehicle performance, ensuring that drivers can enjoy a smooth, responsive, and reliable driving experience. For car enthusiasts, mechanics, or simply someone looking to maintain their vehicle's integrity, understanding the complexities and innovations behind the clutch master cylinder line can lead to more informed purchasing decisions and significantly enhance driving satisfaction. Whether it's for a daily commuter vehicle or a track racer, choosing the right clutch master cylinder line is crucial for achieving peak performance and reliability.

In terms of expertise, a deep understanding of hydraulic systems is imperative for those involved in designing or maintaining clutch master cylinder lines. Knowledge of fluid dynamics, pressure constants, and material science enables professionals to optimize these lines for varied automotive needs—whether it's a high-performance sports car requiring rapid gear shifts or a heavy-duty truck demanding durability under load. The authoritativeness of brands specializing in clutch master cylinder lines can often be judged by their adherence to industry standards. ISO certification or compliance with SAE standards serves as an indicator of a manufacturer’s commitment to quality and reliability. Brands with a strong history in automotive components often have extensive testing protocols in place to simulate real-world driving conditions, ensuring that their products perform flawlessly under stress. Trustworthiness in the world of automotive parts translates to innovation backed by proven results. Brands focusing on clutch master cylinder lines often build trust by engaging with the automotive community, taking feedback from professional drivers, mechanics, and everyday users. Publishing case studies that document performance improvements, or offering extended warranties, reinforces consumer confidence in their products. Trusted brands also maintain transparency regarding the construction and capabilities of their clutch lines, often providing detailed specifications and compatibility guides to assist with selection and installation. Ultimately, the clutch master cylinder line is a testament to the symbiotic relationship between engineering precision and practical application. This product, while often overlooked, is integral to vehicle performance, ensuring that drivers can enjoy a smooth, responsive, and reliable driving experience. For car enthusiasts, mechanics, or simply someone looking to maintain their vehicle's integrity, understanding the complexities and innovations behind the clutch master cylinder line can lead to more informed purchasing decisions and significantly enhance driving satisfaction. Whether it's for a daily commuter vehicle or a track racer, choosing the right clutch master cylinder line is crucial for achieving peak performance and reliability.

Latest news

-

Upgrade Your Clutch System with Premium Hydraulic Clutch LinesNewsJul.31,2025

-

Unlock the Power of Precision with Our Throttle CablesNewsJul.31,2025

-

Unleash Power and Precision with Our Accelerator CablesNewsJul.31,2025

-

Experience Unmatched Safety with Premium Handbrake CablesNewsJul.31,2025

-

Enhance Your Vehicle's Performance with Quality Gear CablesNewsJul.31,2025

-

Workings of Clutch Pipe and Hose SystemsNewsJun.04,2025