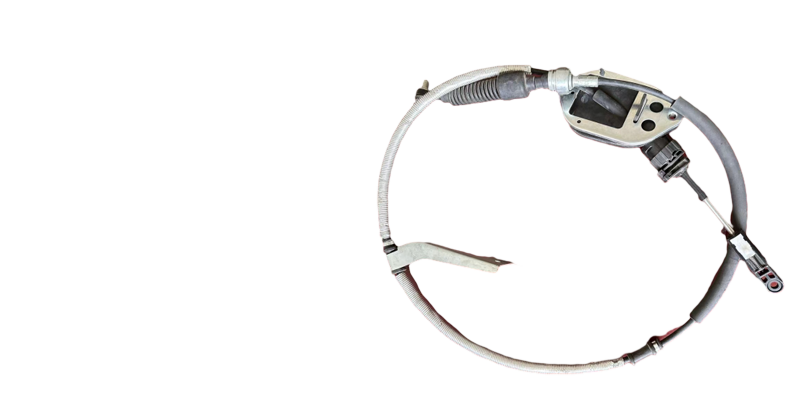

clutch hose pipe

The Importance of Clutch Hose Pipes in Automotive Systems

In the intricate world of automotive engineering, seemingly simple components play crucial roles in the overall performance, safety, and efficiency of vehicles. One such component is the clutch hose pipe, a vital element in the hydraulic clutch system that controls the engagement and disengagement of the clutch in manual transmission vehicles. Understanding the function and significance of clutch hose pipes can provide insights into how they contribute to a vehicle's overall operation.

What is a Clutch Hose Pipe?

A clutch hose pipe, also referred to as a clutch line or clutch hydraulic line, is a flexible tubing that connects the clutch pedal to the master cylinder, which is then linked to the slave cylinder. This piping forms part of a broader hydraulic system responsible for transmitting force from the driver's input at the clutch pedal to the clutch mechanism itself. When the driver presses the pedal, hydraulic fluid is pushed through the clutch hose, activating the slave cylinder, which in turn disengages or engages the clutch, allowing for smooth gear transitions.

The Functionality of Clutch Hose Pipes

The primary function of a clutch hose pipe is to maintain a steady flow of hydraulic fluid while withstanding significant pressure generated during operation. As the driver maneuvers through traffic or accelerates, the engagement and disengagement of the clutch need to be prompt and precise; this process relies heavily on the integrity of the clutch hose pipe. Any obstruction, leakage, or failure in this hose can lead to a range of issues, from diminished vehicle performance to complete clutch failure.

Material and Design Considerations

Clutch hose pipes are typically made from materials designed to endure extreme temperatures, pressure fluctuations, and exposure to hydraulic fluids. Common materials include reinforced rubber, stainless steel, and synthetic polymers. The design of these hoses is equally important, as they must be flexible enough to accommodate movement while maintaining a reliable, leak-proof connection. OEM (Original Equipment Manufacturer) specifications often dictate the design parameters to ensure compatibility and functionality within specific vehicle models.

clutch hose pipe

Common Issues and Maintenance

Over time, clutch hose pipes can suffer from wear and tear, which can compromise their integrity. Common issues include cracking, deterioration from exposure to heat and fluids, and leaks that may occur at connectors or along the hose itself. Drivers may notice signs of failure, such as a spongy clutch pedal, difficulty in gear shifting, or fluid spots under the vehicle.

Regular inspections and maintenance are crucial to prolonging the lifespan of clutch hose pipes. Mechanics often recommend checking these components during routine service intervals, especially in older vehicles or those subjected to extreme driving conditions. Replacing worn or damaged hose pipes is a relatively straightforward process and can prevent costly repairs to the entire clutch system.

The Future of Clutch Hose Technology

As automotive technology evolves, so too does the design and manufacture of clutch hose pipes. Advances in materials science are leading to stronger, lighter, and more durable hoses that can withstand higher pressures and temperatures. The automotive industry is also increasingly focusing on sustainability, resulting in the development of bio-based materials that may soon replace traditional plastics and rubber in future clutch systems.

Additionally, the growth of electric and hybrid vehicles introduces new challenges and innovations in clutch design. While many electric vehicles use single-speed transmissions and do not require a traditional clutch, the technology developed for these systems will likely influence the design of future hybrid systems that do.

Conclusion

In summary, clutch hose pipes play an indispensable role in the operation of manual vehicles. Their ability to effectively transmit hydraulic force is central to the performance of the clutch system. As automotive technology progresses, it is essential to appreciate the engineering behind these components and their impact on vehicle safety and reliability. Regular maintenance and awareness of potential issues can help ensure that drivers enjoy a smooth and efficient driving experience for many miles to come.

-

Upgrade Your Control with Premium Throttle CablesNewsAug.08,2025

-

Stay in Control with Premium Hand Brake CablesNewsAug.08,2025

-

Experience Unmatched Performance with Our Clutch HosesNewsAug.08,2025

-

Ensure Safety and Reliability with Premium Handbrake CablesNewsAug.08,2025

-

Enhance Your Vehicle with High-Performance Clutch LinesNewsAug.08,2025

-

Elevate Your Ride with Premium Gear CablesNewsAug.08,2025