Understanding the Function and Importance of Throttle Cable Wire in Vehicles

Understanding Throttle Cable Wire Essential Components for Optimal Automotive Performance

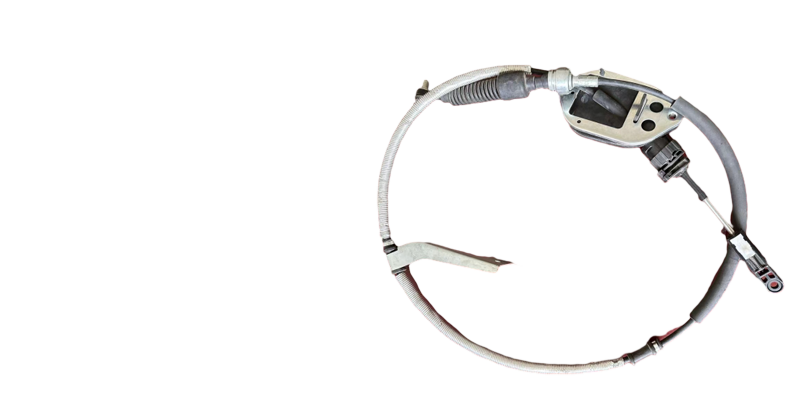

Throttle cable wires are critical components in modern vehicles, contributing significantly to the control and efficiency of engine performance. They serve as the primary link between the accelerator pedal and the throttle body, translating the driver's input into vehicle speed. In this article, we will delve into the significance of throttle cable wires, their construction, functionality, and maintenance tips to ensure optimal performance.

The Role of Throttle Cable Wire

At its core, the throttle cable wire is a flexible steel cable encased in a protective sheath. This setup allows for smooth movement as it transmits the driver’s foot pressure on the accelerator pedal to the throttle butterfly valves located in the engine. When the accelerator pedal is pressed, the cable wire pulls on the throttle lever, thereby opening the throttle and allowing more air into the engine. This increase in air intake directly correlates to the vehicle's speed, making the throttle cable an essential element of the vehicle's acceleration system.

Construction and Materials

Throttle cables are engineered to withstand a variety of environmental stresses. Made from durable materials such as stainless steel, these cables are designed to resist corrosion and wear over time. The outer casing is typically composed of a strong, flexible plastic or rubber material, which protects the cable while allowing for smooth movement within the housing.

The design of throttle cables can vary between vehicles, incorporating different mechanisms for adjustment and installation. Some cables include a simple bolt-and-nut system for securing the cable ends, while others may employ a more complex assembly featuring quick connectors. This variability necessitates that vehicle owners or technicians reference the specific cables designed for their vehicle's make and model, ensuring compatibility and performance.

Types of Throttle Cables

There are generally two types of throttle cable systems mechanical and electronic. Mechanical throttle cables are the traditional form, directly linking the accelerator pedal to the throttle body via a cable. This system offers a straightforward design that many enthusiasts appreciate for its simplicity and reliability.

Alternatively, electronic throttle control (ETC) has gained popularity in modern vehicles. In this system, the traditional cable is replaced by sensors and electronic actuators. When the driver presses the accelerator, a sensor sends a signal to the vehicle's engine control unit (ECU), which then adjusts the throttle opening electronically. While this system reduces the number of mechanical parts and allows for more precise control of engine performance, it can also complicate repairs and maintenance, requiring specialized knowledge and equipment.

throttle cable wire

Signs of Throttle Cable Issues

Like any automotive component, throttle cables can experience wear and tear over time. Common signs of a malfunctioning throttle cable include a sticky accelerator pedal, erratic engine response, or a complete loss of throttle control. If you notice any of these symptoms, it's crucial to inspect the throttle cable for fraying, corrosion, or kinks.

Regular maintenance can help extend the life of your throttle cable. Routine checks can prevent more severe issues down the line. Make it a habit to inspect the cable during your regular vehicle maintenance schedule, looking for signs of wear, and ensuring that the cable operates smoothly without resistance.

Maintenance Tips

1. Visual Inspection Regularly examine the throttle cable for any visible signs of damage, such as frayed wires or excessive wear.

2. Lubrication Keep the cable well-lubricated to prevent sticking and ensure smooth operation. Use a lubricant designed for automotive applications to avoid damage to the cable's protective sheath.

3. Cable Adjustment If you find that the throttle responds sluggishly or inconsistently, it may require adjusting. Refer to your vehicle's service manual for specific adjustment procedures.

4. Replacement If the throttle cable shows significant wear or damage, it is essential to replace it promptly. A compromised cable can lead to dangerous driving conditions, including sudden acceleration or a complete loss of throttle control.

Conclusion

Understanding throttle cable wires is essential for any vehicle owner aiming to maintain or enhance their vehicle’s performance. These seemingly simple components play a pivotal role in your driving experience, translating foot pressure into smooth acceleration. By recognizing the signs of wear, committing to regular maintenance, and knowing when to replace your throttle cable, you can help ensure your vehicle remains responsive and efficient, delivering the performance you expect on the road.

-

Workings of Clutch Pipe and Hose SystemsNewsJun.04,2025

-

The Inner Workings of Hand Brake Cable SystemsNewsJun.04,2025

-

The Secrets of Throttle and Accelerator CablesNewsJun.04,2025

-

The Hidden Lifeline of Your Transmission Gear Shift CablesNewsJun.04,2025

-

Demystifying Gear Cables and Shift LinkagesNewsJun.04,2025

-

Decoding Clutch Line Systems A Comprehensive GuideNewsJun.04,2025