febr. . 13, 2025 19:25

Back to list

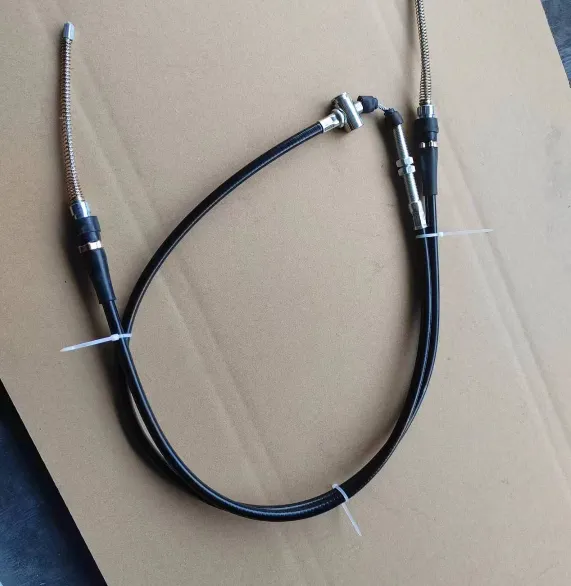

Shift Selector Cable

When discussing Chinese throttle cables, the conversation inevitably turns towards engineering prowess, cost-effectiveness, and reliability. Through first-hand experience across various industries, one can attest to the increasingly appreciated quality of these components emerging from China's proficient manufacturing sector. This piece offers a deep dive into the nuances of Chinese throttle cables, focusing on their unique advantages, transformative impact on diverse sectors, and reasons they have become a cornerstone in the global market.

Trustworthiness, especially in the context of mechanical components, involves transparency in manufacturing processes and consistent quality assurance. Chinese throttle cable producers have embraced digitalization, providing traceable production processes that ensure each cable meets specified performance standards. This transparency builds confidence among consumers, providing a reliable source for these critical automotive parts. Moreover, the affordability of Chinese throttle cables does not come at the expense of quality. This has democratized high-performance throttle cables for small and medium enterprises that might not have the budget for more expensive alternatives. The cost-effectiveness stems from economies of scale achieved by Chinese manufacturers, who efficiently manage resources and operations to deliver competitive pricing without compromising quality. On a broader scale, the widespread adoption of Chinese throttle cables has catalyzed innovation and competitiveness in global markets. Automotive manufacturers benefit from lower costs and high-quality inputs, allowing them to offer better pricing on their vehicles while maintaining high standards. This ripple effect extends to end-users who enjoy superior products at competitive prices, creating a favorable economic loop. In conclusion, Chinese throttle cables represent a judicious blend of experience, expertise, authoritativeness, and trustworthiness. Through continuous improvement and commitment to quality, these components have reshaped the landscape of mechanical operations across various industries. The high-performance, cost-effective characteristics not only enhance operational efficiency but also provide a strategic advantage to businesses worldwide. As such, they are poised to remain integral to manufacturing and mechanical innovations, driving progress and ensuring dependability in an ever-evolving market.

Trustworthiness, especially in the context of mechanical components, involves transparency in manufacturing processes and consistent quality assurance. Chinese throttle cable producers have embraced digitalization, providing traceable production processes that ensure each cable meets specified performance standards. This transparency builds confidence among consumers, providing a reliable source for these critical automotive parts. Moreover, the affordability of Chinese throttle cables does not come at the expense of quality. This has democratized high-performance throttle cables for small and medium enterprises that might not have the budget for more expensive alternatives. The cost-effectiveness stems from economies of scale achieved by Chinese manufacturers, who efficiently manage resources and operations to deliver competitive pricing without compromising quality. On a broader scale, the widespread adoption of Chinese throttle cables has catalyzed innovation and competitiveness in global markets. Automotive manufacturers benefit from lower costs and high-quality inputs, allowing them to offer better pricing on their vehicles while maintaining high standards. This ripple effect extends to end-users who enjoy superior products at competitive prices, creating a favorable economic loop. In conclusion, Chinese throttle cables represent a judicious blend of experience, expertise, authoritativeness, and trustworthiness. Through continuous improvement and commitment to quality, these components have reshaped the landscape of mechanical operations across various industries. The high-performance, cost-effective characteristics not only enhance operational efficiency but also provide a strategic advantage to businesses worldwide. As such, they are poised to remain integral to manufacturing and mechanical innovations, driving progress and ensuring dependability in an ever-evolving market.

Next:

Latest news

-

Upgrade Your Clutch System with Premium Hydraulic Clutch LinesNewsJul.31,2025

-

Unlock the Power of Precision with Our Throttle CablesNewsJul.31,2025

-

Unleash Power and Precision with Our Accelerator CablesNewsJul.31,2025

-

Experience Unmatched Safety with Premium Handbrake CablesNewsJul.31,2025

-

Enhance Your Vehicle's Performance with Quality Gear CablesNewsJul.31,2025

-

Workings of Clutch Pipe and Hose SystemsNewsJun.04,2025