মার্চ . 07, 2025 01:06

Back to list

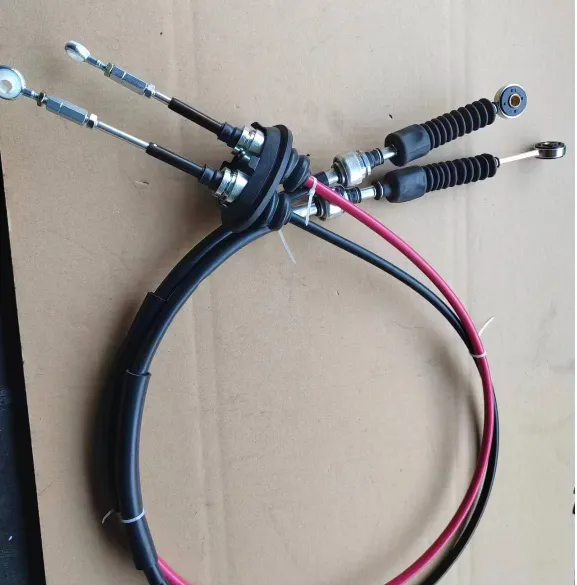

hand throttle cable

Hand throttle cables play an indispensable role in various machinery and vehicles, offering operators precise control over engine speeds. Unlike traditional foot throttles, these cables allow hands-free operation, making them invaluable in diverse applications such as agricultural machinery, industrial equipment, and vintage automobiles. Understanding the nuances of hand throttle cables and selecting the right one can lead to enhanced performance and safety.

Installation best practices also contribute to the overall effectiveness and lifespan of throttle cables. Operators should regularly inspect cables for signs of wear and tear, such as fraying or kinking, which could impede functionality. Lubricating the cable at regular intervals can minimize friction and prevent premature wear. Consulting with a professional during installation can be beneficial, particularly in specialized applications, as this ensures that all components are correctly aligned and secured. For operators and vehicle owners committed to maintaining functional and dependable machinery, investing in premium hand throttle cables is a prudent decision. Reputable manufacturers offer cables that not only meet but often exceed industry standards, ensuring peace of mind and consistent performance. Personal testimonials and experiences from seasoned users further underline the importance of choosing well-engineered products. Moreover, the addition of a hand throttle cable can also enhance safety. Particularly in industrial settings, where precise control over machinery speeds is paramount, these cables contribute to reduced accident rates and improved operational efficiency. By enabling operators to maintain exact engine speeds without continuous pedal adjustments, hand throttle cables ensure smoother operations and facilitate quicker response times in dynamic environments. In conclusion, hand throttle cables serve as vital components across a range of sectors, bringing both practical benefits and enhanced safety to machinery operations. By understanding their application, selecting quality components, and adhering to installation best practices, operators can achieve a notable improvement in equipment performance and longevity. Whether for agricultural use, high-performance racing, or vintage car restoration, these cables bridge the gap between precision control and operational efficiency, underscoring their value to engineers and operators alike. Each decision toward optimizing cable quality and compatibility not only enhances the machinery's utility but also ensures safe and efficient operation across various contexts.

Installation best practices also contribute to the overall effectiveness and lifespan of throttle cables. Operators should regularly inspect cables for signs of wear and tear, such as fraying or kinking, which could impede functionality. Lubricating the cable at regular intervals can minimize friction and prevent premature wear. Consulting with a professional during installation can be beneficial, particularly in specialized applications, as this ensures that all components are correctly aligned and secured. For operators and vehicle owners committed to maintaining functional and dependable machinery, investing in premium hand throttle cables is a prudent decision. Reputable manufacturers offer cables that not only meet but often exceed industry standards, ensuring peace of mind and consistent performance. Personal testimonials and experiences from seasoned users further underline the importance of choosing well-engineered products. Moreover, the addition of a hand throttle cable can also enhance safety. Particularly in industrial settings, where precise control over machinery speeds is paramount, these cables contribute to reduced accident rates and improved operational efficiency. By enabling operators to maintain exact engine speeds without continuous pedal adjustments, hand throttle cables ensure smoother operations and facilitate quicker response times in dynamic environments. In conclusion, hand throttle cables serve as vital components across a range of sectors, bringing both practical benefits and enhanced safety to machinery operations. By understanding their application, selecting quality components, and adhering to installation best practices, operators can achieve a notable improvement in equipment performance and longevity. Whether for agricultural use, high-performance racing, or vintage car restoration, these cables bridge the gap between precision control and operational efficiency, underscoring their value to engineers and operators alike. Each decision toward optimizing cable quality and compatibility not only enhances the machinery's utility but also ensures safe and efficient operation across various contexts.

Latest news

-

Upgrade Your Clutch System with Premium Hydraulic Clutch LinesNewsJul.31,2025

-

Unlock the Power of Precision with Our Throttle CablesNewsJul.31,2025

-

Unleash Power and Precision with Our Accelerator CablesNewsJul.31,2025

-

Experience Unmatched Safety with Premium Handbrake CablesNewsJul.31,2025

-

Enhance Your Vehicle's Performance with Quality Gear CablesNewsJul.31,2025

-

Workings of Clutch Pipe and Hose SystemsNewsJun.04,2025