Jan . 14, 2025 13:41

Back to list

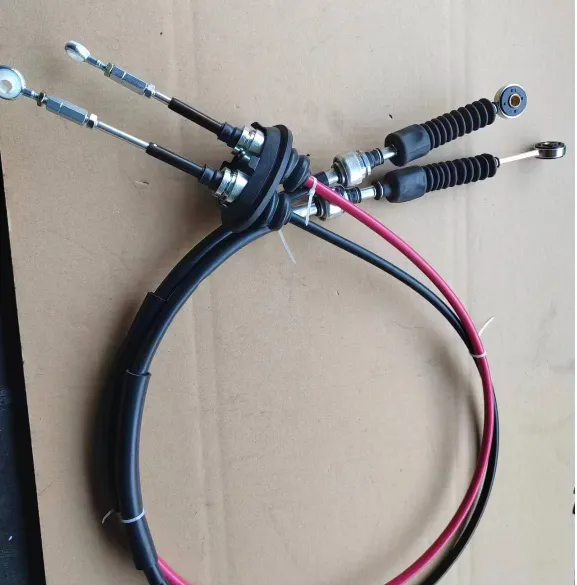

universal handbrake cable

For those deeply entrenched in the world of mechanical repairs and automotive maintenance, understanding the universal choke cable is fundamental. This crucial component plays a pivotal role in ensuring the smooth operation of various types of machinery, from lawnmowers to heavy-duty equipment. Having personally dissected and refurbished countless machines over the years, I’ve acquired profound insights into the functionality and significance of the universal choke cable.

Installation expertise further cements the status of a universal choke cable as an indispensable ally in machinery operation. Proper alignment during installation guarantees seamless operation, reducing wear on the cable itself. It’s not just about connecting parts; it’s about understanding the symbiosis between the cable’s movement and the engine’s response. A well-installed cable provides immediate feedback and precision control, vital for equipment used in precision-demanding tasks. Trustworthiness in universal choke cables is another cornerstone in ensuring efficient operation. Authentic manufacturers offer cables that adhere to international standards, providing a warranty—a testament to the reliability of their products. Counterfeit cables, on the other hand, often lack the resilience and accuracy found in genuine products. Opting for certified cables reduces long-term maintenance costs and guarantees peace of mind. The authorities in mechanical engineering and automotive technology persistently emphasize ongoing education and hands-on experience as the benchmarks of expertise. Their publications form the bedrock of our understanding, offering the latest updates and emerging innovations. Staying informed about developments in universal choke cable manufacturing and materials science ensures that one remains ahead in the field—ready to offer insights based on the latest available data and technology. In conclusion, understanding, selecting, and maintaining a universal choke cable transcends mere functionality. It’s a blend of expertise, experience, and a commitment to quality. Mechanics and hobbyists alike benefit from recognizing the value these cables bring, ensuring their equipment runs smoother, longer, and more efficiently. Trusting in quality products and maintaining a continuous thirst for knowledge lays the groundwork for a successful and enduring engagement with mechanical systems.

Installation expertise further cements the status of a universal choke cable as an indispensable ally in machinery operation. Proper alignment during installation guarantees seamless operation, reducing wear on the cable itself. It’s not just about connecting parts; it’s about understanding the symbiosis between the cable’s movement and the engine’s response. A well-installed cable provides immediate feedback and precision control, vital for equipment used in precision-demanding tasks. Trustworthiness in universal choke cables is another cornerstone in ensuring efficient operation. Authentic manufacturers offer cables that adhere to international standards, providing a warranty—a testament to the reliability of their products. Counterfeit cables, on the other hand, often lack the resilience and accuracy found in genuine products. Opting for certified cables reduces long-term maintenance costs and guarantees peace of mind. The authorities in mechanical engineering and automotive technology persistently emphasize ongoing education and hands-on experience as the benchmarks of expertise. Their publications form the bedrock of our understanding, offering the latest updates and emerging innovations. Staying informed about developments in universal choke cable manufacturing and materials science ensures that one remains ahead in the field—ready to offer insights based on the latest available data and technology. In conclusion, understanding, selecting, and maintaining a universal choke cable transcends mere functionality. It’s a blend of expertise, experience, and a commitment to quality. Mechanics and hobbyists alike benefit from recognizing the value these cables bring, ensuring their equipment runs smoother, longer, and more efficiently. Trusting in quality products and maintaining a continuous thirst for knowledge lays the groundwork for a successful and enduring engagement with mechanical systems.

Next:

Latest news

-

Upgrade Your Clutch System with Premium Hydraulic Clutch LinesNewsJul.31,2025

-

Unlock the Power of Precision with Our Throttle CablesNewsJul.31,2025

-

Unleash Power and Precision with Our Accelerator CablesNewsJul.31,2025

-

Experience Unmatched Safety with Premium Handbrake CablesNewsJul.31,2025

-

Enhance Your Vehicle's Performance with Quality Gear CablesNewsJul.31,2025

-

Workings of Clutch Pipe and Hose SystemsNewsJun.04,2025